Table of Contents

Fabrication en usine-API 5CT N80-Q N80-1-Boîtier de tubes en acier sans soudure

Progrès dans la fabrication en usine-Tubes en acier sans soudure API 5CT N80-Q N80-1-Casing

En plus des progrès dans les techniques de fabrication de l’acier, les équipements de fabrication et les processus de contrôle qualité, des développements significatifs ont également eu lieu dans la conception et l’ingénierie des tubes en acier sans soudure à boîtier API 5CT N80-Q N80-1. Ces développements ont conduit à l’optimisation de la conception des tubes pour améliorer les performances et la fiabilité, ainsi qu’au développement de nouveaux revêtements et traitements de surface pour améliorer la résistance à la corrosion et prolonger la durée de vie des tubes dans des environnements difficiles.

Dans l’ensemble, les progrès réalisés en usine La fabrication de tubes en acier sans soudure à boîtier API 5CT N80-Q N80-1 a abouti à des tubes offrant des performances, une fiabilité et une longévité améliorées dans les applications pétrolières et gazières. Ces progrès ont été motivés par la demande croissante de tubes de haute qualité capables de résister aux conditions d’exploitation difficiles rencontrées dans l’industrie pétrolière et gazière. En conséquence, l’avenir semble prometteur pour le développement continu de processus et de technologies de fabrication en usine qui amélioreront encore la qualité et les performances des tubes en acier sans soudure pour boîtier API 5CT N80-Q N80-1.

Advancements in Factory Manufacturing-API 5CT N80-Q N80-1-Casing Seamless Steel Tubing

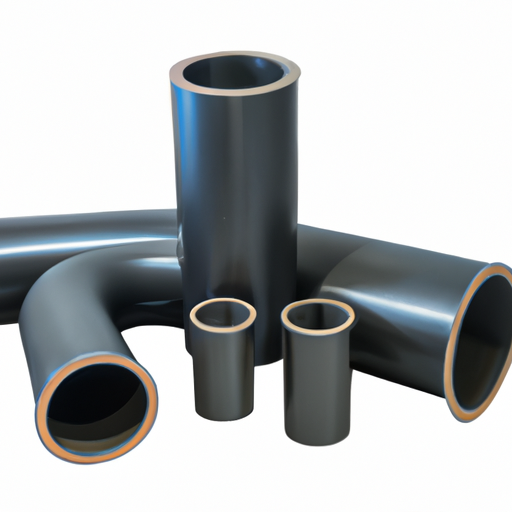

In recent years, there have been significant advancements in the factory manufacturing of API 5CT N80-Q N80-1 casing seamless steel tubing. This type of tubing is widely used in the oil and gas industry for various applications, including drilling, production, and transportation of oil and Natural Gas. The demand for high-quality tubing that can withstand harsh operating conditions has led to the development of new manufacturing processes and technologies that have improved the quality and performance of API 5CT N80-Q N80-1 casing seamless steel tubing.

One of the key advancements in factory manufacturing of API 5CT N80-Q N80-1 casing seamless steel tubing is the use of advanced steelmaking techniques. These techniques allow for the production of steel with improved mechanical properties, such as higher strength and toughness, which are essential for withstanding the high pressures and temperatures encountered in oil and gas wells. Additionally, advanced steelmaking techniques have also led to the development of steel with enhanced corrosion resistance, which is crucial for ensuring the longevity of tubing in corrosive environments.

Another important advancement in factory manufacturing of API 5CT N80-Q N80-1 casing seamless steel tubing is the use of state-of-the-art manufacturing equipment and processes. Modern manufacturing facilities are equipped with advanced machinery and automation systems that allow for the precise and efficient production of tubing with tight dimensional tolerances and consistent mechanical properties. This level of precision and consistency is essential for ensuring the reliability and performance of tubing in demanding oil and gas applications.

Furthermore, advancements in factory manufacturing of API 5CT N80-Q N80-1 casing seamless steel tubing have also led to improvements in quality control and testing processes. Modern manufacturing facilities are equipped with sophisticated inspection and Testing Equipment that allows for the thorough evaluation of tubing to ensure it meets the required specifications and standards. This includes non-destructive testing methods, such as ultrasonic testing and electromagnetic testing, which can detect defects and imperfections in tubing that could compromise its integrity and performance.

In addition to advancements in steelmaking techniques, manufacturing equipment, and quality control processes, there have also been significant developments in the design and engineering of API 5CT N80-Q N80-1 casing seamless steel tubing. These developments have led to the optimization of tubing designs to improve performance and reliability, as well as the development of new coatings and surface treatments to enhance corrosion resistance and extend the service life of tubing in harsh environments.

Overall, the advancements in factory manufacturing of API 5CT N80-Q N80-1 casing seamless steel tubing have resulted in tubing that offers improved performance, reliability, and longevity in oil and gas applications. These advancements have been driven by the increasing demand for high-quality tubing that can withstand the challenging operating conditions encountered in the oil and gas industry. As a result, the future looks promising for the continued development of factory manufacturing processes and technologies that will further enhance the quality and performance of API 5CT N80-Q N80-1 casing seamless steel tubing.