Table of Contents

Avantages de l’utilisation de tuyaux en acier sans soudure ASTM A106B A178C A210A1 St42 St45 St35.8 pour les applications industrielles

Comparaison des matériaux de tubes en acier au carbone à paroi épaisse de grand diamètre : ASTM A106B contre A178C contre A210A1 contre St42 contre St45 contre St35.8

Lors de la comparaison de ces matériaux, il est important de prendre en compte des facteurs tels que la résistance, la durabilité, la soudabilité et la formabilité. Les normes ASTM A106B et A178C sont toutes deux connues pour leur résistance élevée à la traction et à la corrosion, ce qui les rend adaptées aux applications à haute température. L’A210A1, quant à lui, est connu pour sa bonne soudabilité et sa formabilité, ce qui le rend adapté aux applications à basse et moyenne pression.

St42, St45 et St35.8 sont tous connus pour leur haute résistance et leur durabilité, ce qui les rend idéaux pour applications structurelles. Cependant, St42 et St45 sont souvent préférés pour les applications où une résistance plus élevée est requise, tandis que St35.8 est couramment utilisé dans les applications où la formabilité est une considération clé.

En conclusion, lors de la sélection d’un matériau pour l’acier au carbone à paroi épaisse de grand diamètre tubes, il est important de considérer les exigences spécifiques de votre projet. ASTM A106B, A178C, A210A1, St42, St45 et St35.8 ont tous leurs propres propriétés et caractéristiques qui les rendent adaptés à différentes applications. En évaluant soigneusement les forces et les faiblesses de chaque matériau, vous pourrez choisir le matériau adapté à votre projet et assurer sa réussite.

Comparison of Large-Diameter Thick-Walled Carbon Steel Tube Materials: ASTM A106B vs. A178C vs. A210A1 vs. St42 vs. St45 vs. St35.8

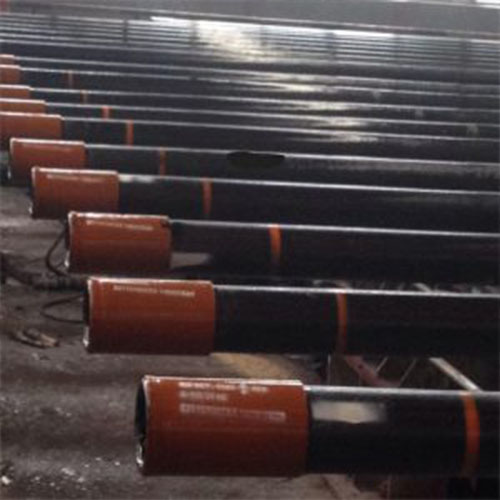

When it comes to choosing the right material for large-diameter thick-walled carbon steel tubes, there are several options available in the market. Among the most commonly used materials are ASTM A106B, A178C, A210A1, St42, St45, and St35.8 seamless Steel Pipes. Each of these materials has its own unique properties and characteristics that make them suitable for different applications. In this article, we will compare these materials to help you make an informed decision when selecting the right material for your project.

ASTM A106B is a seamless carbon steel pipe that is commonly used in high-temperature applications. It has excellent strength and durability, making it ideal for use in industries such as oil and gas, petrochemical, and power generation. A106B is known for its high tensile strength and resistance to corrosion, making it a popular choice for applications where reliability and performance are crucial.

A178C is another seamless carbon steel pipe that is commonly used in industrial applications. It is known for its high thermal conductivity and excellent weldability, making it suitable for applications where heat transfer is important. A178C is often used in Heat Exchangers, Boilers, and other high-temperature applications where thermal efficiency is a key consideration.

A210A1 is a seamless carbon steel pipe that is commonly used in low and medium pressure applications. It has good weldability and formability, making it suitable for a wide range of applications. A210A1 is often used in industries such as construction, automotive, and manufacturing, where a combination of strength and formability is required.

St42, St45, and St35.8 are all seamless carbon steel pipes that are commonly used in structural applications. These materials are known for their high strength and durability, making them ideal for use in construction, infrastructure, and other heavy-duty applications. St42, St45, and St35.8 are often used in the fabrication of bridges, buildings, and other structures where strength and reliability are paramount.

https://www.youtube.com/watch?v=zdG0-AKio40

When comparing these materials, it is important to consider factors such as strength, durability, weldability, and formability. ASTM A106B and A178C are both known for their high tensile strength and resistance to corrosion, making them suitable for high-temperature applications. A210A1, on the other hand, is known for its good weldability and formability, making it suitable for low and medium pressure applications.

St42, St45, and St35.8 are all known for their high strength and durability, making them ideal for structural applications. However, St42 and St45 are often preferred for applications where higher strength is required, while St35.8 is commonly used in applications where formability is a key consideration.

In conclusion, when selecting a material for large-diameter thick-walled carbon steel tubes, it is important to consider the specific requirements of your project. ASTM A106B, A178C, A210A1, St42, St45, and St35.8 all have their own unique properties and characteristics that make them suitable for different applications. By carefully evaluating the strengths and weaknesses of each material, you can choose the right material for your project and ensure its success.