Table of Contents

Avantages de l’utilisation de tuyaux sans soudure en acier au carbone A35 A36 A106 A53 Sch 40 ASTM

Applications des tubes creux étirés à froid dans l’industrie pétrolière et gazière

https://www.youtube.com/watch?v=pE2PEEU66NM

Comprendre les différences entre les tuyaux et tubes en acier API 5L

Lorsqu’il s’agit de choisir le bon type de tuyau ou de tube en acier pour votre projet, il est important de comprendre les différences entre les différentes options disponibles sur le marché. Deux choix populaires pour les applications industrielles sont les tuyaux et tubes en acier API 5L. Les deux sont couramment utilisés dans l’industrie pétrolière et gazière, ainsi que dans la construction et la fabrication. Cependant, il existe des distinctions clés entre les deux qui peuvent avoir un impact sur leurs performances et leur adéquation à des applications spécifiques.

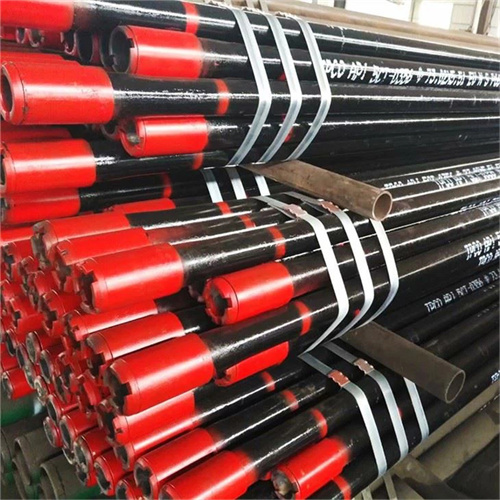

Le tuyau en acier API 5L est un type de tuyau en acier au carbone sans soudure conçu pour le transport de fluides et de gaz à haute pression et haute température. environnements. Il est fabriqué selon les normes de l’American Petroleum Institute (API), qui fixent des exigences strictes en matière de composition chimique, de propriétés mécaniques et de tests du tuyau. Le tube en acier API 5L est disponible en différentes qualités, telles que A35, A36, A106 et A53, avec différentes spécifications d’épaisseur de paroi, de diamètre et de longueur.

D’autre part, le tube en acier API 5L est un type de tube cylindrique creux. structure utilisée pour des applications structurelles, telles que dans la construction de bâtiments, de ponts et de machines. Contrairement aux tuyaux en acier, conçus pour le transport de fluides, les tubes en acier sont principalement utilisés à des fins de support structurel et de support de charge. Le tube en acier API 5L est également fabriqué selon les normes API, avec des exigences spécifiques en matière de dimensions, de tolérances et de finition de surface.

L’une des principales différences entre les tuyaux et tubes en acier API 5L est leur processus de fabrication. Les tuyaux en acier sont généralement produits par un processus appelé étirage à froid sans soudure, dans lequel une billette d’acier solide est chauffée puis percée pour créer un tube creux. Ce processus donne une finition de surface lisse et uniforme, sans coutures ni soudures susceptibles de affaiblir la structure. En revanche, les tubes en acier sont souvent produits par un processus appelé laminage à chaud, dans lequel une billette d’acier est chauffée puis passée à travers une série de rouleaux pour la façonner en tube. Ce processus peut entraîner une finition de surface plus rugueuse et nécessiter un traitement supplémentaire pour obtenir les dimensions et tolérances souhaitées.

Une autre différence importante entre les tuyaux et tubes en acier API 5L est leur application. Les tuyaux en acier sont généralement utilisés pour transporter des fluides et des gaz, tels que le pétrole, le gaz, l’eau et la vapeur, dans des pipelines et des systèmes de canalisations. Il est conçu pour résister à des pressions et des températures élevées, ce qui le rend adapté aux environnements industriels difficiles. Les tubes en acier, quant à eux, sont utilisés pour des applications structurelles où la résistance et la durabilité sont primordiales. Il est couramment utilisé dans les projets de construction, tels que les charpentes de bâtiments, les colonnes de support et les fermes, où il doit supporter de lourdes charges et résister à la flexion et à la torsion.

En conclusion, alors que les tuyaux et tubes en acier API 5L sont tous deux des composants essentiels dans diverses industries , ils répondent à des objectifs différents et possèdent des caractéristiques distinctes qui les rendent adaptés à des applications spécifiques. Comprendre les différences entre les deux peut vous aider à prendre une décision éclairée lors de la sélection du bon type de produit en acier pour votre projet. Que vous ayez besoin d’un tuyau en acier au carbone sans soudure pour le transport de fluides ou d’un tube en acier creux pour le support structurel, connaître les principales distinctions entre le tuyau et le tube en acier API 5L peut vous assurer de choisir le produit adapté à vos besoins.

Carbon Steel seamless pipes are essential components in the oil and gas industry, providing a reliable and efficient means of Transporting fluids such as gas and oil. Among the various types of carbon steel seamless pipes available in the market, the A35, A36, A106, A53 Sch 40 ASTM carbon steel seamless pipe cold drawn hollow tube stands out for its superior quality and performance.

The cold drawn hollow tube seamless gas oil API 5L steel pipe tube is a popular choice for many applications in the oil and gas industry due to its durability, strength, and resistance to corrosion. This type of pipe is manufactured using a cold drawing process, which involves pulling a solid steel billet through a die to create a seamless tube with a smooth surface finish. This process results in a pipe that is free from seams and welds, making it ideal for high-pressure and high-temperature applications.

One of the key advantages of using cold drawn hollow tube seamless gas oil API 5L steel pipe tube in the oil and gas industry is its ability to withstand extreme conditions. These pipes are designed to handle a wide range of temperatures and pressures, making them suitable for use in offshore drilling rigs, refineries, and pipelines. Additionally, the seamless construction of these pipes reduces the risk of leaks and failures, ensuring the safe and efficient transportation of fluids.

Another important application of cold drawn hollow tube seamless gas oil API 5L steel pipe tube in the oil and gas industry is in the construction of pipelines. These pipes are used to transport oil and gas from production sites to refineries and distribution centers, providing a reliable and cost-effective means of transportation. The seamless construction of these pipes minimizes the risk of corrosion and erosion, ensuring the long-term integrity of the pipeline system.

In addition to their use in pipelines, cold drawn hollow tube seamless gas oil API 5L steel pipe tube is also used in the construction of storage tanks and Pressure Vessels. These pipes are designed to withstand high pressures and temperatures, making them ideal for storing and transporting fluids such as oil, gas, and water. The seamless construction of these pipes ensures a tight seal, preventing leaks and ensuring the Safety of the storage system.

Overall, the A35, A36, A106, A53 Sch 40 ASTM carbon steel seamless pipe cold drawn hollow tube seamless gas oil API 5L steel pipe tube is a versatile and reliable choice for a wide range of applications in the oil and gas industry. Its superior quality, durability, and resistance to corrosion make it an ideal choice for use in pipelines, storage tanks, and pressure vessels. Whether used in offshore drilling rigs or refineries, these pipes provide a safe and efficient means of transporting fluids, ensuring the smooth operation of the oil and gas industry.

Understanding the Differences Between API 5L Steel Pipe and Tube

When it comes to choosing the right type of steel pipe or tube for your project, it’s important to understand the differences between various options available in the market. Two popular choices for industrial applications are API 5L steel pipe and tube. Both are commonly used in the oil and gas industry, as well as in construction and manufacturing. However, there are key distinctions between the two that can impact their performance and suitability for specific applications.

API 5L steel pipe is a type of seamless carbon steel pipe that is designed for transporting fluids and gases in high-pressure and high-temperature environments. It is manufactured according to the American Petroleum Institute (API) standards, which set strict requirements for the chemical composition, mechanical properties, and testing of the pipe. API 5L steel pipe is available in various grades, such as A35, A36, A106, and A53, with different specifications for wall thickness, diameter, and length.

On the other hand, API 5L steel tube is a type of hollow cylindrical structure that is used for structural applications, such as in the construction of buildings, bridges, and machinery. Unlike steel pipe, which is designed for fluid transportation, steel tube is primarily used for structural support and load-bearing purposes. API 5L steel tube is also manufactured according to API standards, with specific requirements for dimensions, tolerances, and surface finish.

One of the key differences between API 5L steel pipe and tube is their manufacturing process. Steel pipe is typically produced through a process called seamless cold drawing, where a solid billet of steel is heated and then pierced to create a hollow tube. This process results in a smooth and uniform surface finish, with no seams or welds that can weaken the structure. In contrast, steel tube is often produced through a process called hot rolling, where a steel billet is heated and then passed through a series of rollers to shape it into a tube. This process can result in a rougher surface finish and may require additional processing to achieve the desired dimensions and tolerances.

Another important difference between API 5L steel pipe and tube is their application. Steel pipe is typically used for transporting fluids and gases, such as oil, gas, water, and steam, in pipelines and piping systems. It is designed to withstand high pressures and temperatures, making it suitable for harsh industrial environments. Steel tube, on the other hand, is used for structural applications where strength and durability are paramount. It is commonly used in construction projects, such as building frames, support columns, and trusses, where it must bear heavy loads and resist bending and twisting.

In conclusion, while API 5L steel pipe and tube are both essential components in various industries, they serve different purposes and have distinct characteristics that make them suitable for specific applications. Understanding the differences between the two can help you make an informed decision when selecting the right type of steel product for your project. Whether you need a seamless carbon steel pipe for fluid transportation or a hollow steel tube for structural support, knowing the key distinctions between API 5L steel pipe and tube can ensure that you choose the right product for your needs.