Table of Contents

Benefits of Fiber Core Wire Rope

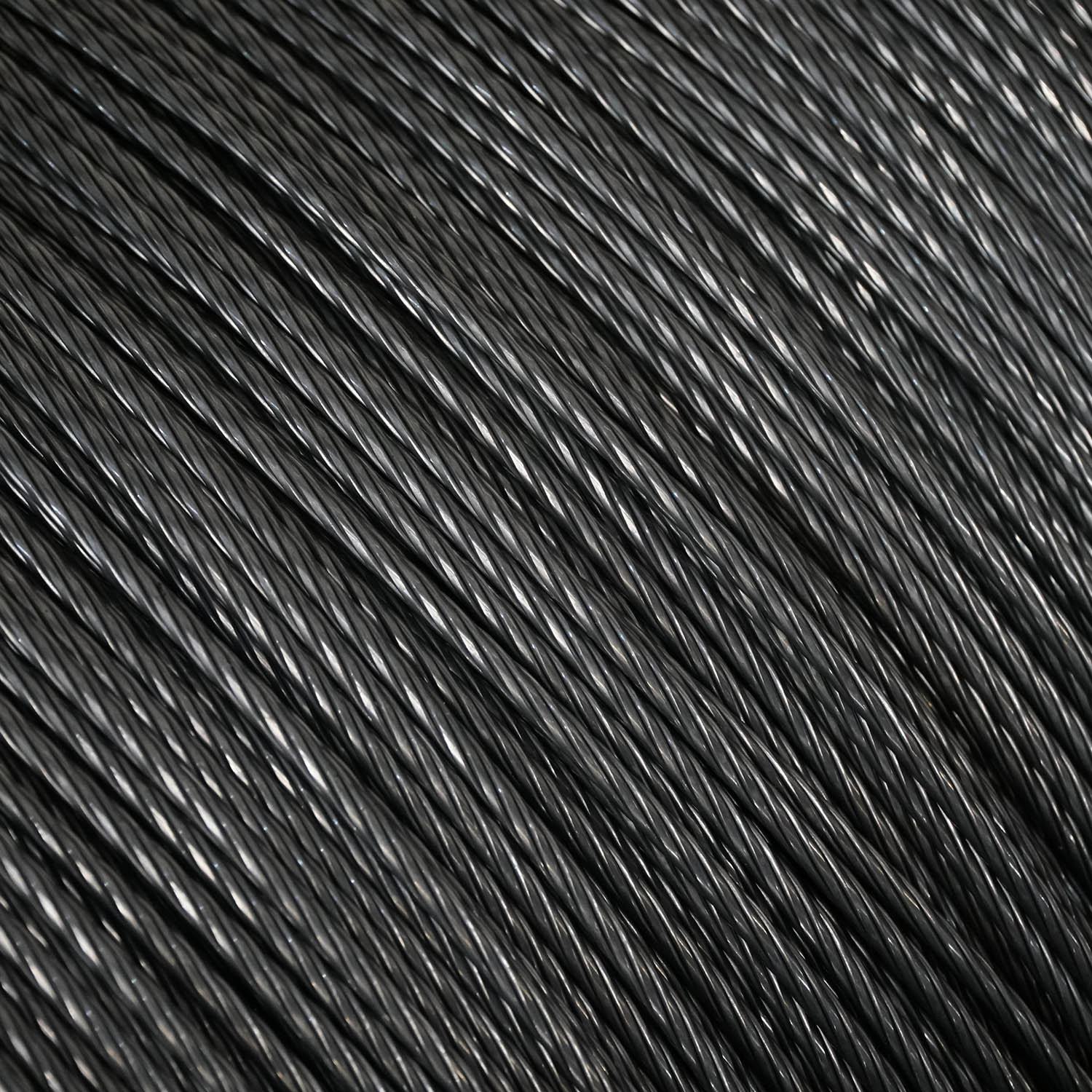

Wire ropes are essential tools in various industries, providing strength and durability for lifting and pulling heavy loads. When it comes to choosing the right wire rope for your specific application, one important factor to consider is the core material. Two common types of wire rope cores are fiber core and steel core. In this article, we will explore the benefits of using fiber core wire rope.

Fiber core wire rope is constructed with a core made of natural or synthetic fibers, such as sisal, polypropylene, or polyethylene. These fibers provide a cushioning effect between the strands of the outer wire rope, which helps to reduce wear and tear on the rope itself. This cushioning effect also helps to absorb shock loads, making fiber core wire rope ideal for applications where sudden impacts or dynamic loads are common.

One of the key benefits of fiber core wire rope is its flexibility. The natural or synthetic fibers used in the core allow the rope to bend and flex more easily than steel core wire rope. This flexibility is especially important in applications where the wire rope needs to navigate around corners or Obstacles. Fiber core wire rope is less likely to kink or become damaged when bent, making it a more versatile option for a wide range of lifting and pulling tasks.

Another advantage of fiber core wire rope is its lightweight construction. The natural or synthetic fibers used in the core are much lighter than steel, which can reduce the overall weight of the wire rope. This can be beneficial in applications where weight is a concern, such as in mobile crane operations or when lifting loads in confined spaces. The lighter weight of fiber core wire rope also makes it easier to handle and transport, saving time and effort for workers.

In addition to its flexibility and lightweight construction, fiber core wire rope also offers excellent resistance to corrosion. The natural or synthetic fibers used in the core are not susceptible to rust or corrosion like steel, making fiber core wire rope a durable and long-lasting option for outdoor or marine applications. This resistance to corrosion helps to extend the lifespan of the wire rope, reducing the need for frequent replacements and maintenance.

Furthermore, fiber core wire rope is known for its excellent fatigue resistance. The cushioning effect provided by the core helps to distribute stress more evenly throughout the rope, reducing the risk of fatigue failure over time. This makes fiber core wire rope a reliable choice for applications where the wire rope is subjected to repeated bending or flexing, such as in overhead crane systems or Elevator Hoists.

In conclusion, fiber core wire rope offers a range of benefits that make it a versatile and reliable option for a wide range of lifting and pulling applications. Its flexibility, lightweight construction, resistance to corrosion, and fatigue resistance make it a popular choice for industries such as construction, mining, and marine. When considering which type of wire rope to use for your specific application, be sure to weigh the advantages of fiber core wire rope against other options to determine the best fit for your needs.