Table of Contents

Factory Manufacturing-API 5CT N80-Q N80-1-Casing Seamless Steel Tubing

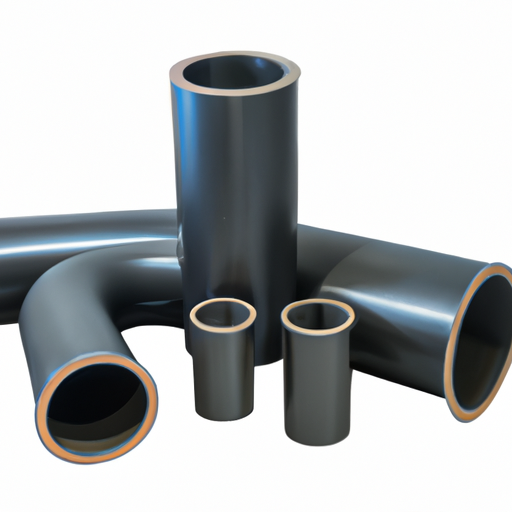

In the realm of industrial manufacturing, the production of API 5CT N80-Q and N80-1 casing seamless steel tubing stands as a testament to precision engineering and robust material science. These tubing products are essential components in the oil and gas industry, where they endure extreme conditions and play a critical role in well drilling and completion operations.

API 5CT N80-Q and N80-1 casing seamless steel tubing are designed to meet stringent standards set forth by the American Petroleum Institute (API). These standards ensure that the tubing possesses high strength, excellent resistance to corrosion, and reliable performance under varying temperatures and pressures encountered in oil and gas wells.

The manufacturing process begins with the careful selection of raw materials. High-quality steel is chosen for its specific mechanical properties and chemical composition, which are crucial for achieving the desired strength and durability required for oilfield applications. The steel undergoes rigorous testing to ensure it meets API specifications before being processed further.

Once the raw material is approved, it undergoes a series of manufacturing steps. The first step is hot rolling, where the steel is heated to a high temperature and passed through rollers to achieve the desired dimensions and thickness. This process not only shapes the steel but also refines its microstructure to enhance its mechanical properties.

Next, the hot-rolled tubes undergo a seamless process where they are pierced and drawn over a mandrel. This seamless method ensures uniformity in wall thickness and eliminates the risk of weak points that could compromise the tubing’s integrity under stress. The tubes are then heat-treated to improve their mechanical properties, such as tensile strength and hardness, making them capable of withstanding the demanding conditions of oil and gas operations.

Quality control is paramount throughout the manufacturing process. Each tube undergoes rigorous inspection and testing to verify dimensional accuracy, mechanical properties, and adherence to API standards. Non-destructive testing techniques, such as ultrasonic and electromagnetic inspection, detect any internal or surface defects that could compromise the tubing’s performance in the field.

Once the tubes pass inspection, they are marked according to API specifications and prepared for final finishing processes, including cutting to length and threading. The threading process is critical as it enables the tubing to be connected securely within the oil well, forming a sealed barrier against pressure and fluid ingress.

The finished API 5CT N80-Q and N80-1 casing seamless steel tubing represents the culmination of advanced manufacturing techniques and stringent quality assurance measures. These products are not only durable and reliable but also crucial for maintaining the integrity and efficiency of oil and gas wells worldwide.

In conclusion, the manufacturing of API 5CT N80-Q and N80-1 casing seamless steel tubing exemplifies the intersection of technology, engineering excellence, and industrial standards. From the careful selection of raw materials to the precision manufacturing processes and rigorous quality control measures, each step ensures that the tubing meets the exacting requirements of the oil and gas industry. As global energy demands continue to grow, these products will remain indispensable in supporting safe and efficient oilfield operations, underscoring their pivotal role in the modern industrial landscape.

Advancements in Factory Manufacturing-API 5CT N80-Q N80-1-Casing Seamless Steel Tubing

In recent years, there have been significant advancements in the factory manufacturing of API 5CT N80-Q N80-1 casing seamless steel tubing. This type of tubing is widely used in the oil and gas industry for various applications, including drilling, production, and transportation of oil and Natural Gas. The demand for high-quality tubing that can withstand harsh operating conditions has led to the development of new manufacturing processes and technologies that have improved the quality and performance of API 5CT N80-Q N80-1 casing seamless steel tubing.

One of the key advancements in factory manufacturing of API 5CT N80-Q N80-1 casing seamless steel tubing is the use of advanced steelmaking techniques. These techniques allow for the production of steel with improved mechanical properties, such as higher strength and toughness, which are essential for withstanding the high pressures and temperatures encountered in oil and gas wells. Additionally, advanced steelmaking techniques have also led to the development of steel with enhanced corrosion resistance, which is crucial for ensuring the longevity of tubing in corrosive environments.

Another important advancement in factory manufacturing of API 5CT N80-Q N80-1 casing seamless steel tubing is the use of state-of-the-art manufacturing equipment and processes. Modern manufacturing facilities are equipped with advanced machinery and automation systems that allow for the precise and efficient production of tubing with tight dimensional tolerances and consistent mechanical properties. This level of precision and consistency is essential for ensuring the reliability and performance of tubing in demanding oil and gas applications.

Furthermore, advancements in factory manufacturing of API 5CT N80-Q N80-1 casing seamless steel tubing have also led to improvements in quality control and testing processes. Modern manufacturing facilities are equipped with sophisticated inspection and Testing Equipment that allows for the thorough evaluation of tubing to ensure it meets the required specifications and standards. This includes non-destructive testing methods, such as ultrasonic testing and electromagnetic testing, which can detect defects and imperfections in tubing that could compromise its integrity and performance.

In addition to advancements in steelmaking techniques, manufacturing equipment, and quality control processes, there have also been significant developments in the design and engineering of API 5CT N80-Q N80-1 casing seamless steel tubing. These developments have led to the optimization of tubing designs to improve performance and reliability, as well as the development of new coatings and surface treatments to enhance corrosion resistance and extend the service life of tubing in harsh environments.

Overall, the advancements in factory manufacturing of API 5CT N80-Q N80-1 casing seamless steel tubing have resulted in tubing that offers improved performance, reliability, and longevity in oil and gas applications. These advancements have been driven by the increasing demand for high-quality tubing that can withstand the challenging operating conditions encountered in the oil and gas industry. As a result, the future looks promising for the continued development of factory manufacturing processes and technologies that will further enhance the quality and performance of API 5CT N80-Q N80-1 casing seamless steel tubing.