Table of Contents

Benefits of Using Emulsified Cutting Fluid in Manufacturing Processes

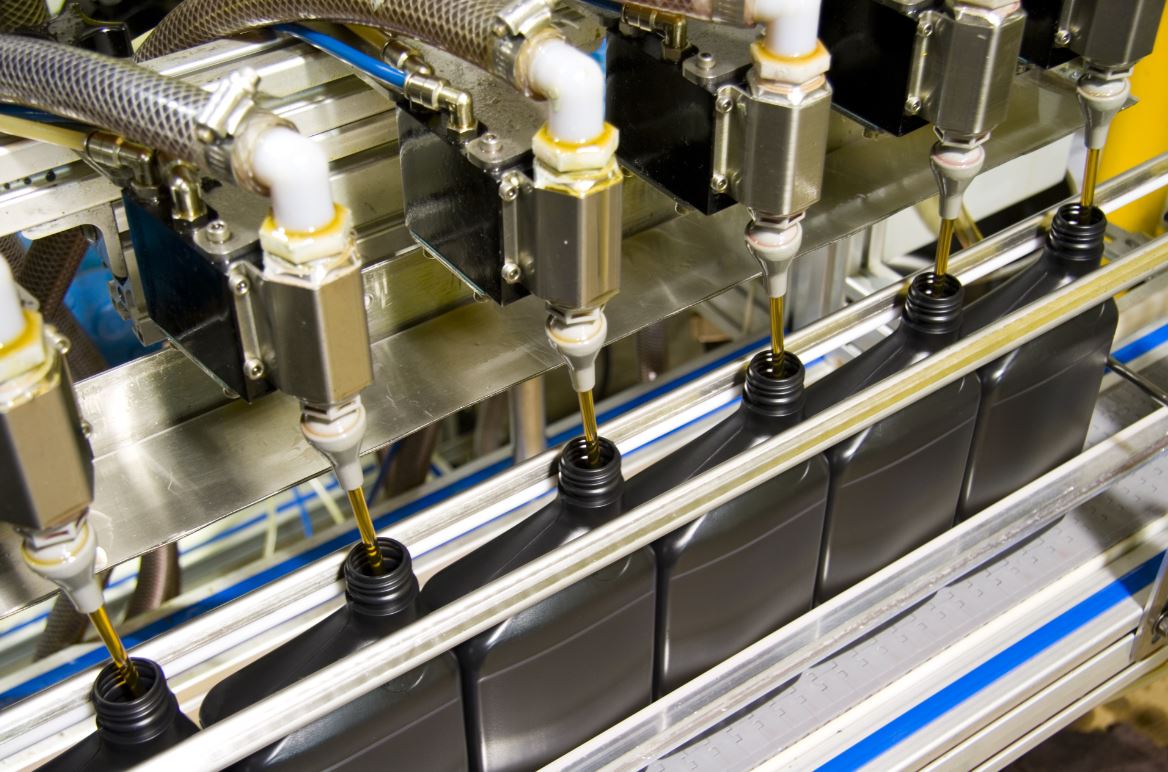

Emulsified cutting fluid is a crucial component in the manufacturing industry, providing numerous benefits to the Machining process. This type of cutting fluid is a mixture of oil and water, which helps to reduce friction and heat during cutting operations. Emulsified cutting fluid is widely used in various manufacturing processes, including milling, drilling, and turning, due to its ability to improve tool life, surface finish, and overall machining efficiency.

One of the key benefits of using emulsified cutting fluid is its ability to improve tool life. By reducing friction and heat generated during cutting operations, emulsified cutting fluid helps to prolong the life of cutting tools. This not only saves money on tool replacement costs but also ensures that the tools perform at their optimal level for a longer period of time. Additionally, the use of emulsified cutting fluid can help to prevent tool wear and damage, resulting in higher quality machined parts.

In addition to improving tool life, emulsified cutting fluid also helps to enhance surface finish. The lubricating properties of the cutting fluid help to create a smoother surface on the machined part, reducing the need for additional finishing processes. This not only saves time and money but also ensures that the final product meets the required specifications. The use of emulsified cutting fluid can also help to reduce the occurrence of burrs and other surface defects, resulting in a higher quality finished product.

Furthermore, emulsified cutting fluid can improve overall machining efficiency. By reducing friction and heat, the cutting fluid helps to increase cutting speeds and feeds, allowing for faster machining operations. This can Lead to increased productivity and reduced cycle times, ultimately improving the overall efficiency of the manufacturing process. Additionally, the use of emulsified cutting fluid can help to reduce the risk of machine downtime due to tool wear or damage, further enhancing productivity.

Another benefit of using emulsified cutting fluid is its ability to improve chip evacuation. The lubricating properties of the cutting fluid help to reduce chip buildup on the cutting tool, allowing for more efficient chip evacuation. This helps to prevent chip recutting and tool damage, resulting in a smoother machining process. Improved chip evacuation also helps to maintain a cleaner work Environment, reducing the risk of contamination and improving overall workplace Safety.

In conclusion, emulsified cutting fluid offers a wide range of benefits for manufacturing processes. From improving tool life and surface finish to enhancing machining efficiency and chip evacuation, the use of emulsified cutting fluid can significantly impact the overall quality and productivity of machining operations. With its affordable cost and high quality, emulsified cutting fluid from China high-quality factories is a valuable investment for any manufacturing facility looking to optimize their machining processes.

How to Choose the Right Emulsified Cutting Fluid for Your Factory

Emulsified cutting fluids are essential in the metalworking industry as they help to improve tool life, increase machining efficiency, and provide better surface finish. Choosing the right emulsified cutting fluid for your factory is crucial to ensure optimal performance and cost-effectiveness. With so many options available in the market, it can be overwhelming to make the right choice. However, by considering a few key factors, you can select the best emulsified cutting fluid for your specific needs.

One of the most important factors to consider when choosing an emulsified cutting fluid is the type of metal being machined. Different metals have different machining characteristics, and therefore require specific types of cutting fluids. For example, Aluminum machining requires a cutting fluid with excellent lubricity and cooling properties, while Stainless Steel machining requires a cutting fluid with good anti-corrosion properties. By understanding the properties of the metal being machined, you can select a cutting fluid that is tailored to your specific needs.

Another important factor to consider is the machining process itself. Different machining processes, such as turning, milling, drilling, and grinding, have different requirements when it comes to cutting fluids. For example, grinding operations require a cutting fluid with good flushing properties to remove swarf and heat from the cutting zone, while turning operations require a cutting fluid with good lubricity to reduce friction and heat generation. By understanding the specific requirements of your machining process, you can select a cutting fluid that is best suited to your needs.

In addition to considering the type of metal and machining process, it is also important to consider the environmental impact of the cutting fluid. Emulsified cutting fluids contain various additives and Chemicals that can be harmful to the environment if not properly disposed of. Therefore, it is important to choose a cutting fluid that is environmentally friendly and complies with regulations. Look for cutting fluids that are biodegradable, non-toxic, and free from harmful chemicals such as chlorine and sulfur. By choosing an environmentally friendly cutting fluid, you can reduce your factory’s environmental footprint and contribute to a more sustainable future.

Cost is another important factor to consider when choosing an emulsified cutting fluid for your factory. While high-quality cutting fluids may come with a higher price tag, they can also provide significant cost savings in the long run. High-quality cutting fluids are more effective at extending tool life, reducing machine downtime, and improving machining efficiency. By investing in a high-quality cutting fluid, you can save money on tooling costs, maintenance costs, and energy costs. Additionally, some cutting fluid suppliers offer bulk discounts and special promotions, so be sure to shop around and compare prices to find the best deal.

In conclusion, choosing the right emulsified cutting fluid for your factory is essential to ensure optimal performance, cost-effectiveness, and environmental sustainability. By considering factors such as the type of metal being machined, the machining process, environmental impact, and cost, you can select a cutting fluid that is tailored to your specific needs. With the right cutting fluid, you can improve tool life, increase machining efficiency, and achieve better surface finish, ultimately leading to a more productive and profitable factory.

Comparing Different High-Quality Emulsified Cutting Fluid Brands in China

Emulsified cutting fluids are essential in the metalworking industry as they help to improve tool life, surface finish, and overall machining efficiency. With the market flooded with various brands claiming to offer high-quality emulsified cutting fluids, it can be challenging to determine which one is the best for your specific needs. In China, there are several high-quality factories that produce emulsified cutting fluids at an affordable price. In this article, we will compare some of the top brands in China to help you make an informed decision.

One of the leading emulsified cutting fluid brands in China is XYZ Fluids. XYZ Fluids is known for its high-quality products that are specifically designed for heavy-duty machining operations. Their cutting fluids are formulated to provide excellent lubrication and cooling properties, which help to extend tool life and improve machining efficiency. Additionally, XYZ Fluids offers a wide range of products to cater to different machining applications, making them a versatile choice for metalworking professionals.

Another reputable brand in China is ABC Lubricants. ABC Lubricants is known for its environmentally friendly cutting fluids that are free from harmful chemicals. Their cutting fluids are biodegradable and non-toxic, making them a safe and sustainable option for metalworking operations. In addition to being eco-friendly, ABC Lubricants’ cutting fluids are also highly effective in reducing friction and heat generation during machining, resulting in improved surface finish and dimensional accuracy.

One of the key factors to consider when choosing an emulsified cutting fluid is its performance in different machining operations. Some cutting fluids are specifically designed for high-speed machining, while others are better suited for heavy-duty cutting applications. It is essential to select a cutting fluid that Matches the specific requirements of your machining operation to achieve optimal results.

In terms of affordability, many Chinese factories offer high-quality emulsified cutting fluids at a competitive price. By purchasing directly from a factory in China, you can save on costs and get access to premium-quality products without compromising on performance. Additionally, some factories offer bulk discounts and customized solutions to meet the unique needs of their customers, making them a cost-effective option for metalworking professionals.

| Label | Products |

| www.mogenoils.com/product-category/product/ | industrial oil |

When comparing different high-quality emulsified cutting fluid brands in China, it is essential to consider factors such as performance, sustainability, and affordability. By choosing a reputable brand that offers superior lubrication and cooling properties, environmentally friendly solutions, and competitive pricing, you can enhance the efficiency and productivity of your metalworking operations.

In conclusion, emulsified cutting fluids play a crucial role in the metalworking industry by improving tool life, surface finish, and overall machining efficiency. With several high-quality factories in China offering affordable and premium-quality cutting fluids, metalworking professionals have access to a wide range of options to meet their specific needs. By comparing different brands based on performance, sustainability, and affordability, you can make an informed decision and select the best emulsified cutting fluid for your machining operation.