Table of Contents

Importance of Dissolved Oxygen Meter Specifications in Aquaculture

Dissolved oxygen meter specifications play a crucial role in the field of aquaculture, where the accurate measurement of dissolved oxygen Levels in water is essential for maintaining the health and well-being of aquatic organisms. The specifications of a dissolved oxygen meter determine its accuracy, reliability, and suitability for specific aquaculture applications. In this article, we will explore the importance of dissolved oxygen meter specifications in aquaculture and their impact on the overall success of aquaculture operations.

One of the key specifications to consider when selecting a dissolved oxygen meter for aquaculture is its measurement range. Different aquatic environments may require different measurement Ranges to accurately capture the variations in dissolved oxygen levels. For instance, in freshwater aquaculture, the dissolved oxygen levels may typically range from 0 to 20 mg/L, while in marine aquaculture, the range may extend up to 30 mg/L. Therefore, a dissolved oxygen meter with a wide measurement range can provide more flexibility and accuracy in monitoring dissolved oxygen levels across various aquaculture settings.

Furthermore, the accuracy and precision of a dissolved oxygen meter are critical factors that directly impact the reliability of the measurements. High-quality meters with precise Sensors and advanced calibration mechanisms can provide more accurate readings, allowing aquaculture operators to make informed decisions about oxygen supplementation, water quality management, and overall environmental conditions within aquaculture systems. Additionally, the stability and response time of the meter are important considerations, as they determine how quickly and consistently the meter can provide reliable measurements in dynamic aquaculture environments.

In addition to the technical specifications, the durability and ruggedness of a dissolved oxygen meter are essential for its performance in aquaculture settings. Aquaculture operations often involve harsh and demanding conditions, including exposure to water, Chemicals, and physical impacts. Therefore, a robust and waterproof design, along with corrosion-resistant materials, is crucial for ensuring the longevity and reliability of the meter in aquaculture applications.

Another important aspect of dissolved oxygen meter specifications is the availability of additional features and connectivity options. Advanced meters may offer features such as data logging, automatic temperature compensation, and compatibility with digital communication protocols, allowing for seamless integration with aquaculture Monitoring Systems and data management platforms. These features can enhance the efficiency and convenience of monitoring dissolved oxygen levels in aquaculture facilities, enabling proactive management and optimization of water quality parameters.

In conclusion, the specifications of a dissolved oxygen meter are paramount in the context of aquaculture, as they directly influence the accuracy, reliability, and

The Impact of Absorbent Cotton on Sound Quality in Recording Studios

Absorbent cotton is a crucial material in the field of acoustics, playing a significant role in shaping the sound quality of recording studios and other acoustic environments. Its ability to absorb sound waves makes it a valuable tool for controlling reverberation and echoes, ultimately influencing the overall acoustic performance of a space. In this article, we will explore the impact of absorbent cotton on sound quality in recording studios and various acoustic environments.

When it comes to recording studios, the quality of sound is of utmost importance. Absorbent cotton, often used in the form of Acoustic Panels or sound-absorbing baffles, is employed to minimize the unwanted reflections of sound within the studio space. By absorbing sound waves, it helps to reduce reverberation and echoes, creating a more controlled and balanced acoustic Environment. This is particularly crucial when recording Music, vocals, or any other audio content, as it ensures that the captured sound is clear and free from unwanted distortions.

The performance of absorbent cotton in recording studios is not limited to controlling reverberation. It also contributes to creating a more accurate listening environment. By minimizing the impact of reflections and echoes, absorbent cotton helps to maintain the integrity of the original sound, allowing for more precise monitoring and mixing of audio recordings. This is essential for achieving high-quality, professional-grade results in the field of music production and audio engineering.

Beyond recording studios, absorbent cotton also plays a vital role in various other acoustic environments. In spaces such as auditoriums, theaters, and conference rooms, the use of absorbent cotton helps to enhance speech intelligibility and overall sound clarity. By reducing the effects of reverberation and echoes, it ensures that the audience can hear and understand spoken words or musical performances with greater clarity and definition.

In addition to its impact on sound quality, absorbent cotton also contributes to the overall comfort and aesthetics of a space. Acoustic panels and treatments made from absorbent cotton are available in a variety of designs and colors, allowing for customization to suit the specific needs and visual preferences of different environments. This not only adds to the functionality of the material but also enhances the overall ambiance and appeal of the space.

In conclusion, absorbent cotton plays a crucial role in shaping the sound quality of recording studios and various acoustic environments. Its ability to control reverberation, minimize echoes, and enhance speech intelligibility makes it an indispensable tool for achieving optimal acoustic performance. Whether in the context of music production, live performances, or everyday

Optimizing Acoustic Environments with Absorbent Cotton: A Comprehensive Guide

Optimizing Acoustic Environments with Absorbent Cotton: A Comprehensive Guide

When it comes to creating optimal acoustic environments, absorbent materials play a crucial role in managing sound reflections and reverberations. One such material that has proven effective in this regard is absorbent cotton. In this comprehensive guide, we will delve into the specifications of dissolved oxygen meters, exploring their key features and functionalities to help you make informed decisions when selecting the right equipment for your acoustic projects.

| Model | pH/ORP-9500 pH/ORP Meter |

| Range | 0-14 pH; -2000 – +2000mV |

| Accuracy | \\u00b10.1pH; \\u00b12mV |

| Temp. Comp. | Automatic temperature compensation |

| Oper. Temp. | Normal 0\\uff5e50\\u2103; High temp 0\\uff5e100\\u2103 |

| Sensor | pH double/triple sensor; ORP sensor |

| Display | LCD Screen |

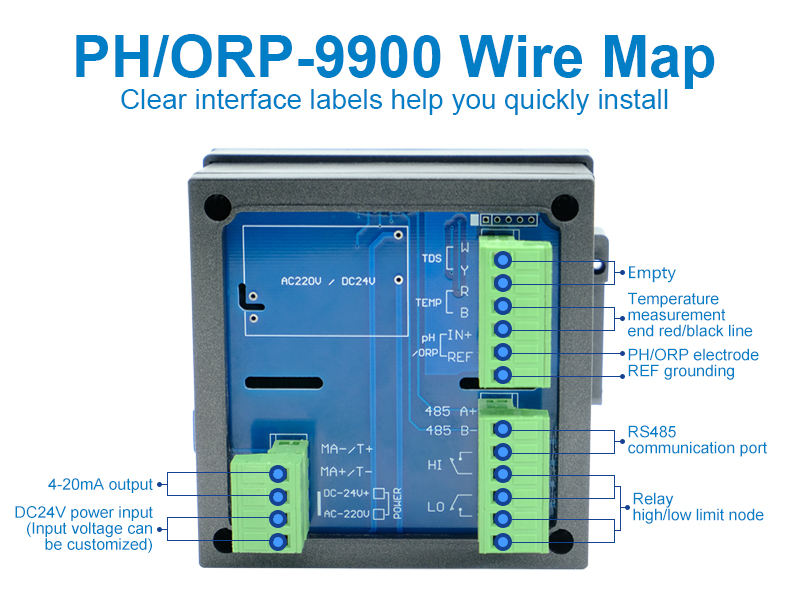

| Communication | 4-20mA output/RS485 |

| Output | High/Low limit triple relay control |

| Power | AC 220V\\u00b110% 50/60Hz or AC 110V\\u00b110% 50/60Hz or DC24V/0.5A |

| Working Environment | Ambient temperature:0\\uff5e50\\u2103 |

| Relative humidity\\u226485% | |

| Dimensions | 96\\u00d796\\u00d7132mm(H\\u00d7W\\u00d7L) |

| Hole Size | 92\\u00d792mm(H\\u00d7W) |

| Installation Mode | Embedded |

First and foremost, it is essential to understand the purpose of a dissolved oxygen meter. These devices are designed to measure the concentration of oxygen dissolved in a liquid, typically water. In the context of acoustic environments, the specifications of a dissolved oxygen meter become relevant when considering the impact of oxygen levels on the performance and longevity of absorbent cotton materials.

One of the primary specifications to consider when evaluating a dissolved oxygen meter is its measurement range. This parameter indicates the minimum and maximum levels of dissolved oxygen that the meter can accurately detect. For acoustic applications, it is important to select a meter with a measurement range that aligns with the expected oxygen levels in the environment where the absorbent cotton will be deployed. This ensures that the meter can provide precise readings within the relevant oxygen concentration range, allowing for effective monitoring of environmental conditions.

In addition to measurement range, the accuracy and precision of a dissolved oxygen meter are critical factors to consider. The accuracy of the meter refers to its ability to provide measurements that are close to the true value of the dissolved oxygen concentration, while precision relates to the consistency of repeated measurements. When working with absorbent cotton in acoustic environments, maintaining optimal oxygen levels is essential for preserving the material’s acoustic absorption properties. Therefore, selecting a meter with high accuracy and precision ensures reliable monitoring of oxygen levels, enabling proactive adjustments to maintain ideal acoustic conditions.

Furthermore, the response time of a dissolved oxygen meter is an important specification to take into account. This parameter indicates the time it takes for the meter to register a change in dissolved oxygen concentration. In acoustic environments, rapid response times are beneficial for promptly identifying fluctuations in oxygen levels that may impact the performance of absorbent cotton materials. By selecting a meter with a fast response time, acoustic professionals can effectively monitor and address changes in environmental conditions to uphold the acoustic integrity of their spaces.

Another crucial aspect of dissolved oxygen meter specifications is the calibration process. Calibration ensures that the meter provides accurate and reliable measurements by comparing its readings to known standards. When integrating absorbent cotton in acoustic environments