Table of Contents

Sure! Here is a numbered list of blog topics related to the subject you mentioned:

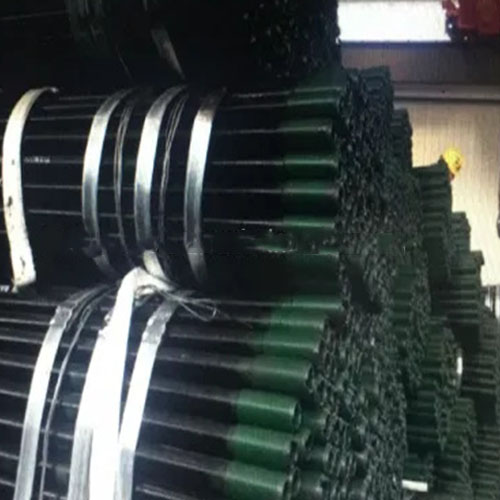

Cold rolled bright high precision steel tubes are a crucial component in various industries, including automotive, machinery, and construction. These tubes are known for their exceptional strength, durability, and precision, making them an ideal choice for applications that require high-performance materials.

1. Understanding Cold Rolled Bright High Precision Steel Tubes

– In this introductory section, we will discuss the fundamentals of cold rolled bright high precision steel tubes. We will explore their composition, manufacturing process, and the benefits they offer over other types of steel tubes.

2. Composition and Properties

– Cold rolled bright high precision steel tubes are typically made from Carbon Steel alloys, such as 1020, 1035, 1045, St52, 4140, 16mncr5, 5120, 52100, and 100gr6. These alloys are carefully selected for their specific properties, including high strength, excellent weldability, and resistance to corrosion.

3. Manufacturing Process

– Cold rolled bright high precision steel tubes are produced through a meticulous manufacturing process. The process involves cold rolling, where a flat steel strip is passed through a series of rollers to reduce its thickness and improve its surface finish. This results in a tube with precise dimensions and a smooth, bright surface.

4. Superior Precision and Dimensional Accuracy

– One of the key advantages of cold rolled bright high precision steel tubes is their exceptional precision and dimensional accuracy. These tubes are manufactured to tight tolerances, ensuring that they meet the exact specifications required for the intended application. This precision allows for seamless integration into complex systems and ensures optimal performance.

5. Versatility and Application

– Cold rolled bright high precision steel tubes find extensive use in a wide range of industries and applications. They are commonly employed in automotive components such as fuel injection systems, steering columns, and Shock Absorbers, where precision and reliability are paramount. These tubes are also used in machinery, hydraulic systems, and construction equipment, where they provide structural support and fluid transmission capabilities.

6. Advantages Over Other Steel Tubes

– Compared to other types of steel tubes, cold rolled bright high precision steel tubes offer several advantages. They possess superior surface finish, which minimizes friction and enhances fluid flow. Additionally, their precise dimensions and tight tolerances result in efficient assembly and reduced wastage. Furthermore, these tubes exhibit excellent resistance to corrosion, ensuring long-lasting performance even in harsh environments.

7. Conclusion

– Cold rolled bright high precision steel tubes are an essential component in numerous industries, thanks to their exceptional strength, durability, and precision. With their precise dimensions, superior surface finish, and resistance to corrosion, these tubes offer unparalleled performance in a variety of applications. Whether in automotive, machinery, or construction, cold rolled bright high precision steel tubes are the