Table of Contents

Understanding the Differences between Cold/Hot Rolled Sch40 Sch80 Sch160 ASTM A53 A106 API 5L Gr. B S235jr Q235 Ss400seamless Casing Oil Tubing in Stock in Tianjin

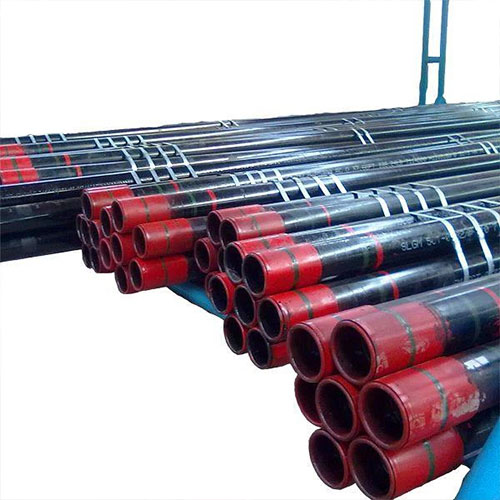

Understanding the differences between cold and hot rolled Sch40 Sch80 Sch160 ASTM A53 A106 API 5L Gr. B S235jr Q235 Ss400seamless casing oil tubing in stock in Tianjin is crucial for those in the oil and gas industry. These products, which are integral to the extraction and transportation of oil and gas, are distinguished by their manufacturing processes, material properties, and applications.

Cold rolled Sch40 Sch80 Sch160 ASTM A53 A106 API 5L Gr. B S235jr Q235 Ss400seamless casing oil tubing is produced through a process that involves rolling the steel at a low temperature. This method results in a product with a smooth surface finish and precise dimensions. The cold rolling process enhances the strength and hardness of the steel by causing the metal to form strain hardening, which occurs when the metal is deformed beyond its yield strength. This makes cold rolled tubing ideal for applications that require high strength and tight tolerances, such as in the construction of oil wells.

On the other hand, hot rolled Sch40 Sch80 Sch160 ASTM A53 A106 API 5L Gr. B S235jr Q235 Ss400seamless casing oil tubing is manufactured by rolling the steel at a high temperature, typically over 1700 degrees Fahrenheit. This process allows the steel to be easily shaped and formed. Hot rolled tubing is characterized by its rough surface finish and less precise dimensions. However, it is more malleable and flexible than its cold rolled counterpart, making it suitable for applications that require the tubing to be bent or shaped, such as in the construction of pipelines.

The material properties of these tubing products also differ. The ASTM A53 A106 API 5L Gr. B S235jr Q235 Ss400seamless casing oil tubing is made from Carbon Steel, which is known for its high tensile strength and durability. This makes it ideal for use in harsh environments, such as in the oil and gas industry. The S235jr Q235 Ss400seamless casing oil tubing, on the other hand, is made from structural steel, which is known for its high yield strength and good weldability. This makes it suitable for use in structural applications, such as in the construction of oil rigs.

In Tianjin, a major hub for the oil and gas industry in China, these products are readily available in stock. This ensures that the needs of the industry are met promptly, reducing downtime and increasing efficiency.

In conclusion, understanding the differences between cold and hot rolled Sch40 Sch80 Sch160 ASTM A53 A106 API 5L Gr. B S235jr Q235 Ss400seamless casing oil tubing is essential for selecting the right product for specific applications in the oil and gas industry. Whether it’s the strength and precision of cold rolled tubing or the malleability and flexibility of hot rolled tubing, each product offers unique advantages that can enhance the efficiency and effectiveness of oil and gas operations.

Exploring the Applications and Benefits of Cold/Hot Rolled Sch40 Sch80 Sch160 ASTM A53 A106 API 5L Gr. B S235jr Q235 Ss400seamless Casing Oil Tubing in Tianjin

The world of industrial manufacturing is a complex one, with a myriad of materials and processes at play. One such material that has gained significant attention in recent years is the Cold/Hot Rolled Sch40 Sch80 Sch160 ASTM A53 A106 API 5L Gr. B S235jr Q235 Ss400seamless Casing Oil Tubing. This product, which is readily available in stock in Tianjin, has a wide range of applications and offers numerous benefits that make it a preferred choice for many industries.

To begin with, the Cold/Hot Rolled Sch40 Sch80 Sch160 ASTM A53 A106 API 5L Gr. B S235jr Q235 Ss400seamless Casing Oil Tubing is a versatile material that can be used in various applications. It is primarily used in the oil and gas industry for the construction of pipelines. The seamless nature of this tubing ensures that there are no weak points or joints that could potentially Lead to leaks or ruptures. This is particularly important in the oil and gas industry, where the safe and efficient transport of these resources is paramount.

https://www.youtube.com/watch?v=J1ao9j7SS_YMoreover, this tubing is also used in the construction industry, particularly in the building of high-rise structures. The strength and durability of this material make it an ideal choice for such applications. It can withstand high Levels of pressure and stress, making it a reliable choice for structures that need to be robust and long-lasting.

In addition to its wide range of applications, the Cold/Hot Rolled Sch40 Sch80 Sch160 ASTM A53 A106 API 5L Gr. B S235jr Q235 Ss400seamless Casing Oil Tubing also offers numerous benefits. One of the main advantages of this material is its resistance to corrosion. This makes it an excellent choice for use in environments where it may be exposed to corrosive substances, such as in the oil and gas industry.

Furthermore, this tubing is also highly resistant to heat, making it suitable for use in high-temperature environments. This is particularly beneficial in industries such as power generation, where materials are often exposed to extreme heat.

Another significant benefit of the Cold/Hot Rolled Sch40 Sch80 Sch160 ASTM A53 A106 API 5L Gr. B S235jr Q235 Ss400seamless Casing Oil Tubing is its cost-effectiveness. Despite its high-quality features and benefits, this material is relatively affordable compared to other similar products on the market. This makes it a cost-effective solution for industries looking to balance quality and affordability.

In conclusion, the Cold/Hot Rolled Sch40 Sch80 Sch160 ASTM A53 A106 API 5L Gr. B S235jr Q235 Ss400seamless Casing Oil Tubing, available in stock in Tianjin, is a versatile and beneficial material that is used in a variety of industries. Its wide range of applications, coupled with its numerous benefits such as corrosion resistance, heat resistance, and cost-effectiveness, make it a preferred choice for many. As the demand for high-quality, durable, and affordable materials continues to grow, it is expected that the popularity of this tubing will continue to rise.