Table of Contents

Benefits of Using China Steel Casing Pipe in Construction Projects

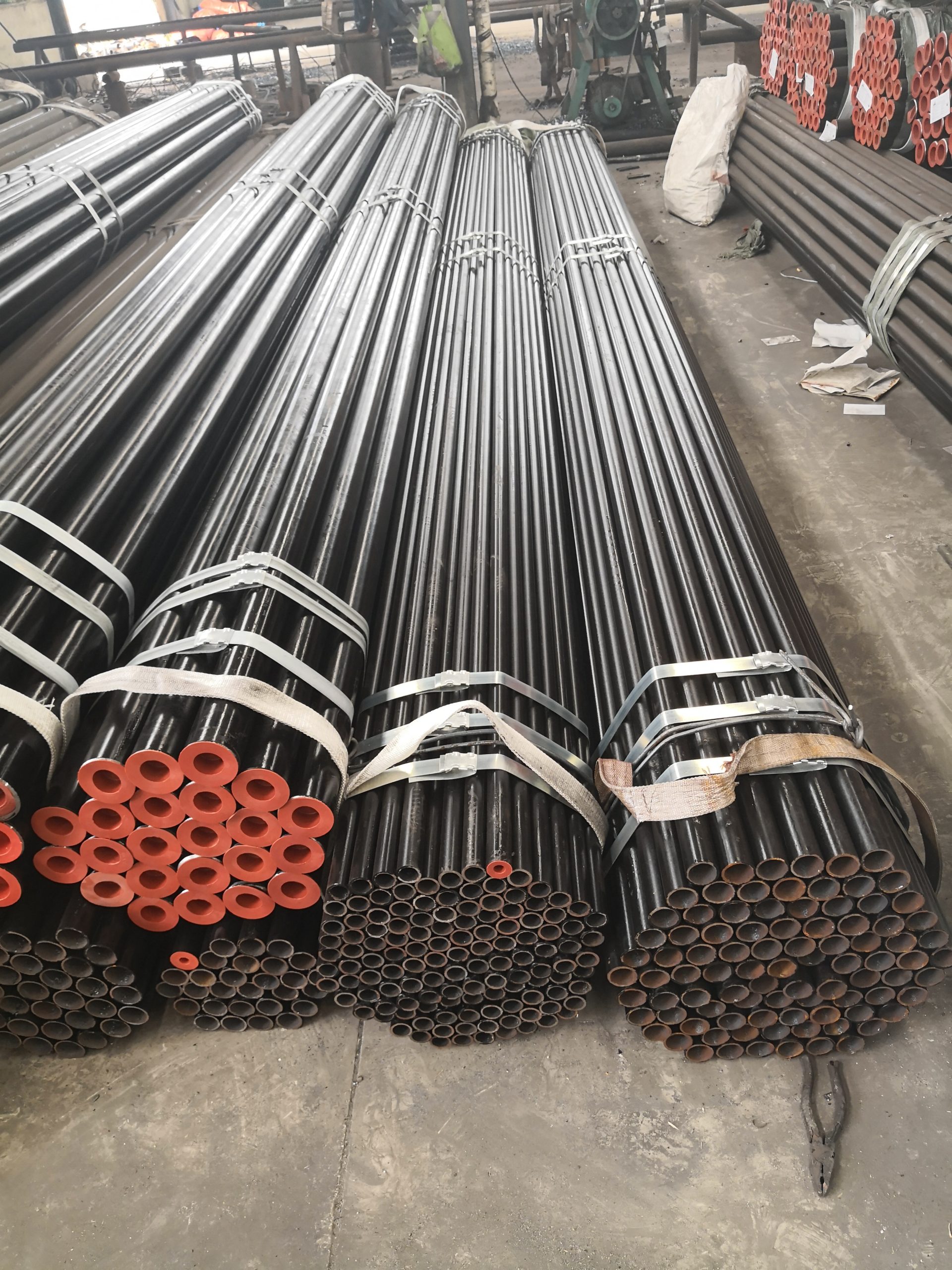

Steel casing pipes are an essential component in various construction projects, providing structural support and protection for underground utilities such as water, gas, and oil pipelines. China has emerged as a leading manufacturer of high-quality steel casing pipes, offering numerous benefits for construction projects around the world.

One of the primary advantages of using China steel casing pipes is their durability and strength. These pipes are made from high-quality steel that is designed to withstand extreme conditions, including high pressure, corrosion, and impact. This makes them ideal for use in construction projects where the pipes are exposed to harsh environments or heavy loads.

In addition to their strength, China steel casing pipes are also known for their versatility. These pipes come in a variety of sizes and thicknesses, making them suitable for a wide range of applications. Whether you need a small diameter pipe for a residential project or a large diameter pipe for a commercial development, China steel casing pipes can meet your requirements.

Furthermore, China steel casing pipes are cost-effective compared to other materials such as concrete or PVC. The initial investment may be higher, but the long-term savings are significant due to the pipes’ durability and low maintenance requirements. This makes them a cost-effective choice for construction projects looking to minimize expenses without compromising on quality.

Another benefit of using China steel casing pipes is their ease of installation. These pipes are lightweight and easy to transport, making them quick and efficient to install on-site. This can help reduce labor costs and shorten project timelines, allowing construction projects to be completed faster and more efficiently.

Moreover, China steel casing pipes are environmentally friendly. Steel is a recyclable material, which means that old pipes can be melted Down and reused to create new products. This helps reduce waste and minimize the environmental impact of construction projects, making China steel casing pipes a sustainable choice for environmentally conscious Developers.

In conclusion, China steel casing pipes offer numerous benefits for construction projects, including durability, strength, versatility, cost-effectiveness, ease of installation, and environmental sustainability. These pipes are a reliable and efficient solution for underground utility protection and structural support, making them a popular choice for developers around the world. Whether you are working on a residential, commercial, or industrial project, China steel casing pipes can meet your needs and exceed your expectations.

How to Choose the Right China Steel Casing Pipe for Your Project

Steel casing pipes are an essential component in various construction projects, including oil and gas drilling, water well drilling, and underground infrastructure development. When it comes to choosing the right steel casing pipe for your project, there are several factors to consider to ensure that you get the best quality and performance.

One of the first things to consider when selecting a steel casing pipe is the material. China is known for producing high-quality steel casing pipes that meet international standards. The most common materials used in manufacturing steel casing pipes are Carbon Steel, Alloy Steel, and Stainless Steel. Each material has its own set of properties that make it suitable for different applications.

Carbon steel is the most commonly used material for steel casing pipes due to its high strength and durability. It is also cost-effective, making it a popular choice for many construction projects. Alloy steel, on the other hand, is a combination of different metals that offer enhanced strength and corrosion resistance. Stainless steel is another popular choice for steel casing pipes, as it is highly resistant to corrosion and can withstand harsh environmental conditions.

In addition to the material, the size and thickness of the steel casing pipe are also important factors to consider. The size of the pipe will depend on the diameter of the borehole or the size of the casing required for the project. The thickness of the pipe will determine its strength and durability. Thicker pipes are more suitable for deep drilling projects or projects that require high-pressure resistance.

Another important consideration when choosing a steel casing pipe is the type of coating or lining applied to the pipe. Coatings and linings are used to protect the pipe from corrosion, abrasion, and other forms of damage. Common coatings used on steel casing pipes include epoxy, polyethylene, and Zinc. Each coating has its own set of properties that make it suitable for different applications.

When selecting a steel casing pipe, it is also important to consider the manufacturing process. China is known for its advanced manufacturing techniques and quality control standards, ensuring that steel casing pipes produced in China meet the highest quality standards. It is important to choose a reputable manufacturer with a proven track record of producing high-quality steel casing pipes.

In conclusion, choosing the right steel casing pipe for your project is essential to ensure its success. Consider factors such as material, size, thickness, coating, and manufacturing process when selecting a steel casing pipe. By choosing a high-quality steel casing pipe from a reputable manufacturer in China, you can ensure that your project is completed safely and efficiently.