Table of Contents

Choosing the Right Casing Drift for Your Well Maintenance

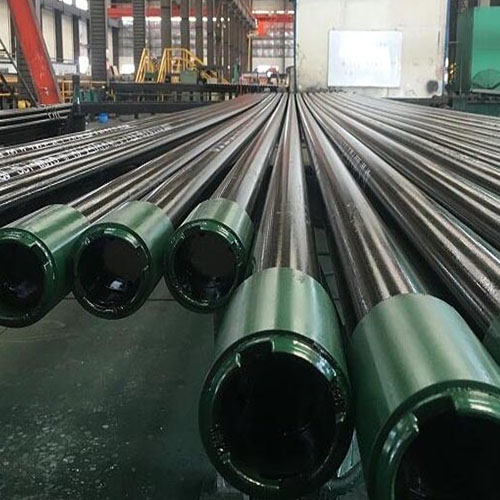

Casing drifts are an essential tool in well maintenance, used to ensure the integrity of the well casing and prevent any obstructions that may hinder the flow of oil or gas. Choosing the right casing drift for your well is crucial to maintaining the efficiency and productivity of your operation. There are several factors to consider when selecting a casing drift, including the size and material of the drift, as well as the specific requirements of your well.

One of the most important considerations when choosing a casing drift is the size of the drift. Casing drifts come in a variety of sizes to accommodate different well casing diameters. It is essential to select a drift that is the correct size for your well casing to ensure a proper fit and effective cleaning. Using a drift that is too small may not effectively remove obstructions, while using a drift that is too large may cause damage to the casing. It is important to accurately measure the diameter of your well casing before selecting a drift to ensure a proper fit.

In addition to size, the material of the casing drift is also an important consideration. Casing drifts are typically made from steel or Aluminum, with steel drifts being more durable and able to withstand greater pressure and wear. Aluminum drifts are lighter and easier to handle, but may not be as durable as steel drifts. The material of the drift should be chosen based on the specific requirements of your well, taking into account factors such as pressure, temperature, and the presence of corrosive substances.

https://www.youtube.com/watch?v=4erHivkeuv4When selecting a casing drift, it is also important to consider the specific requirements of your well. Some wells may have unique characteristics that require a specialized drift, such as a drift with a particular shape or design. It is important to consult with a well maintenance expert to determine the best drift for your specific well conditions. Additionally, it is important to consider the frequency of drift usage and the expected lifespan of the drift when making your selection.

In conclusion, choosing the right casing drift for your well maintenance is essential to ensuring the efficiency and productivity of your operation. Factors such as size, material, and specific well requirements should be carefully considered when selecting a drift. Consulting with a well maintenance expert can help you make an informed decision and ensure that you choose the best drift for your well. By selecting the right casing drift, you can help prevent obstructions, maintain the integrity of your well casing, and maximize the productivity of your operation.