Table of Contents

Benefits of Using ASTM A106B A178C A210A1 St42 St45 St35.8 Seamless Steel Pipe for Industrial Applications

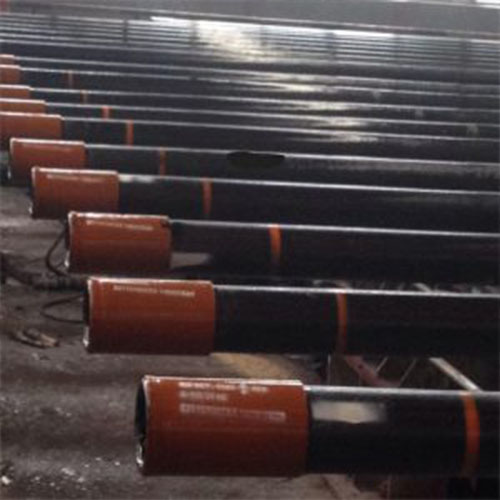

ASTM A106B, A178C, A210A1, St42, St45, and St35.8 seamless Steel Pipes are widely used in various industrial applications due to their high strength, durability, and resistance to corrosion. These pipes are known for their ability to withstand high temperatures and pressures, making them ideal for use in industries such as oil and gas, petrochemical, power generation, and construction.

One of the key benefits of using ASTM A106B, A178C, A210A1, St42, St45, and St35.8 seamless steel pipes is their superior strength and durability. These pipes are made from high-quality Carbon Steel, which gives them the strength to withstand extreme conditions without deforming or breaking. This makes them ideal for use in applications where high pressure and temperature are common, such as in oil and gas pipelines or power generation plants.

Another advantage of using seamless steel pipes is their resistance to corrosion. The seamless construction of these pipes eliminates the need for welding, which can weaken the material and make it more susceptible to corrosion. This makes seamless steel pipes an ideal choice for applications where corrosion resistance is essential, such as in chemical processing plants or offshore drilling platforms.

In addition to their strength and corrosion resistance, ASTM A106B, A178C, A210A1, St42, St45, and St35.8 seamless steel pipes are also known for their uniformity and consistency. The seamless manufacturing process ensures that each pipe is free from defects and has a smooth, even surface finish. This makes them easier to install and reduces the risk of leaks or failures in the system.

Furthermore, seamless steel pipes are known for their high thermal conductivity, which allows for efficient heat transfer in industrial processes. This makes them ideal for use in applications where heat transfer is critical, such as in Heat Exchangers or Boilers. The seamless construction of these pipes also reduces the risk of heat loss or inefficiency, making them a cost-effective choice for industrial applications.

Overall, ASTM A106B, A178C, A210A1, St42, St45, and St35.8 seamless steel pipes offer a range of benefits for industrial applications. Their strength, durability, resistance to corrosion, uniformity, and thermal conductivity make them an ideal choice for a wide range of industries. Whether used in oil and gas pipelines, power generation plants, chemical processing facilities, or construction projects, seamless steel pipes provide reliable performance and long-lasting durability.

Comparison of Large-Diameter Thick-Walled Carbon Steel Tube Materials: ASTM A106B vs. A178C vs. A210A1 vs. St42 vs. St45 vs. St35.8

When it comes to choosing the right material for large-diameter thick-walled carbon steel tubes, there are several options available in the market. Among the most commonly used materials are ASTM A106B, A178C, A210A1, St42, St45, and St35.8 seamless steel pipes. Each of these materials has its own unique properties and characteristics that make them suitable for different applications. In this article, we will compare these materials to help you make an informed decision when selecting the right material for your project.

ASTM A106B is a seamless carbon steel pipe that is commonly used in high-temperature applications. It has excellent strength and durability, making it ideal for use in industries such as oil and gas, petrochemical, and power generation. A106B is known for its high tensile strength and resistance to corrosion, making it a popular choice for applications where reliability and performance are crucial.

A178C is another seamless carbon steel pipe that is commonly used in industrial applications. It is known for its high thermal conductivity and excellent weldability, making it suitable for applications where heat transfer is important. A178C is often used in heat exchangers, boilers, and other high-temperature applications where thermal efficiency is a key consideration.

A210A1 is a seamless carbon steel pipe that is commonly used in low and medium pressure applications. It has good weldability and formability, making it suitable for a wide range of applications. A210A1 is often used in industries such as construction, automotive, and manufacturing, where a combination of strength and formability is required.

St42, St45, and St35.8 are all seamless carbon steel pipes that are commonly used in structural applications. These materials are known for their high strength and durability, making them ideal for use in construction, infrastructure, and other heavy-duty applications. St42, St45, and St35.8 are often used in the fabrication of bridges, buildings, and other structures where strength and reliability are paramount.

https://www.youtube.com/watch?v=zdG0-AKio40

When comparing these materials, it is important to consider factors such as strength, durability, weldability, and formability. ASTM A106B and A178C are both known for their high tensile strength and resistance to corrosion, making them suitable for high-temperature applications. A210A1, on the other hand, is known for its good weldability and formability, making it suitable for low and medium pressure applications.

St42, St45, and St35.8 are all known for their high strength and durability, making them ideal for structural applications. However, St42 and St45 are often preferred for applications where higher strength is required, while St35.8 is commonly used in applications where formability is a key consideration.

In conclusion, when selecting a material for large-diameter thick-walled carbon steel tubes, it is important to consider the specific requirements of your project. ASTM A106B, A178C, A210A1, St42, St45, and St35.8 all have their own unique properties and characteristics that make them suitable for different applications. By carefully evaluating the strengths and weaknesses of each material, you can choose the right material for your project and ensure its success.