Table of Contents

Benefits of Using Asphalt Stripping Inhibitor Additives

Asphalt stripping inhibitor additives are an essential component in the construction and maintenance of roads, highways, and other paved surfaces. These additives play a crucial role in preventing the stripping of asphalt from aggregates, which can Lead to premature pavement failure and costly repairs. In this article, we will explore the benefits of using asphalt stripping inhibitor additives and discuss the importance of understanding the Material Safety Data Sheet (MSDS) for these additives.

One of the primary benefits of using asphalt stripping inhibitor additives is their ability to improve the adhesion between asphalt and aggregates. When asphalt and aggregates do not bond properly, water can seep into the pavement, causing it to deteriorate quickly. By using an asphalt stripping inhibitor additive, the adhesion between asphalt and aggregates is enhanced, resulting in a more durable and long-lasting pavement.

| Number | Product |

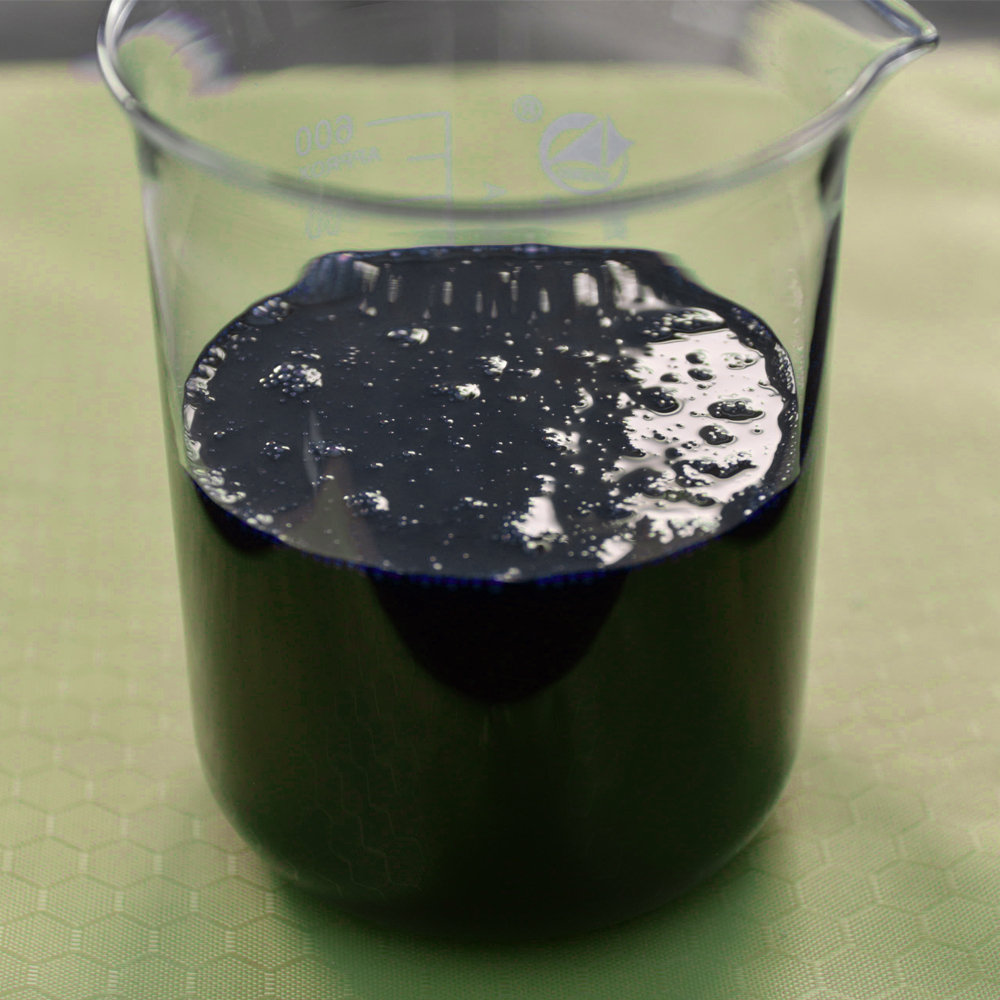

| 1 | Liquid Stripping inhibitor agent |

Additionally, asphalt stripping inhibitor additives help to reduce the risk of moisture damage to the pavement. When water infiltrates the pavement, it can weaken the bond between asphalt and aggregates, leading to stripping and potholes. By using an asphalt stripping inhibitor additive, the pavement becomes more resistant to moisture damage, prolonging its lifespan and reducing the need for frequent repairs.

Furthermore, asphalt stripping inhibitor additives can improve the overall performance of the pavement. By preventing the stripping of asphalt from aggregates, these additives help to maintain the structural integrity of the pavement, ensuring a smooth and safe driving surface for motorists. Additionally, the use of asphalt stripping inhibitor additives can reduce maintenance costs and extend the life of the pavement, saving time and money in the long run.

It is important for contractors and pavement maintenance professionals to be familiar with the Material Safety Data Sheet (MSDS) for asphalt stripping inhibitor additives. The MSDS provides important information about the chemical composition of the additive, as well as guidelines for safe handling, storage, and disposal. By understanding the MSDS for asphalt stripping inhibitor additives, contractors can ensure that they are using the product correctly and taking the necessary precautions to protect themselves and the Environment.

When using asphalt stripping inhibitor additives, it is essential to follow the manufacturer’s instructions carefully. Proper application of the additive is crucial to its effectiveness in preventing asphalt stripping and maintaining the integrity of the pavement. Contractors should also be aware of any potential hazards associated with the additive and take appropriate safety measures to protect themselves and their workers.

In conclusion, asphalt stripping inhibitor additives offer a range of benefits for the construction and maintenance of pavements. By improving adhesion between asphalt and aggregates, reducing moisture damage, and enhancing pavement performance, these additives help to create durable and long-lasting roadways. Understanding the MSDS for asphalt stripping inhibitor additives is essential for safe and effective use, ensuring that contractors can maximize the benefits of these additives while minimizing risks. By incorporating asphalt stripping inhibitor additives into pavement projects, contractors can create high-quality, resilient roadways that stand the test of time.

Understanding the MSDS of Anti-Strip Asphalt Additives

Asphalt stripping is a common issue in the construction industry that can lead to pavement failure and safety hazards. To combat this problem, anti-strip asphalt additives are used to improve the adhesion between asphalt binder and aggregate. One such additive is the asphalt stripping inhibitor, which is designed to prevent moisture from interfering with the bond between the asphalt binder and aggregate. Understanding the Material Safety Data Sheet (MSDS) of anti-strip asphalt additives is crucial for ensuring safe handling and usage of these products.

The MSDS provides important information about the chemical composition of the anti-strip asphalt additive, as well as its potential hazards and safe handling procedures. It is essential for workers to familiarize themselves with the MSDS before using the product to prevent accidents and ensure compliance with safety regulations. The MSDS typically includes information on the physical and chemical properties of the additive, such as its appearance, odor, and pH level. This information can help workers identify the additive and handle it properly.

In addition to physical and chemical properties, the MSDS also provides information on the potential health hazards associated with the anti-strip asphalt additive. This includes details on exposure limits, symptoms of exposure, and first aid measures in case of accidental contact. By understanding the health hazards of the additive, workers can take appropriate precautions to protect themselves and others from harm. This may include wearing Personal Protective Equipment, such as gloves and goggles, when handling the additive.

The MSDS also outlines the proper storage and disposal procedures for the anti-strip asphalt additive. It is important to store the additive in a cool, dry place away from direct sunlight and sources of heat. Improper storage can lead to degradation of the additive and reduce its effectiveness. When disposing of the additive, it is important to follow local regulations and guidelines to prevent environmental contamination.

Furthermore, the MSDS provides information on emergency procedures in case of spills or accidents involving the anti-strip asphalt additive. This includes steps to contain and clean up spills, as well as procedures for handling fires or other emergencies. By being prepared and knowing how to respond to emergencies, workers can minimize the impact of accidents and protect themselves and the environment.

Overall, understanding the MSDS of anti-strip asphalt additives is essential for ensuring safe handling and usage of these products. By familiarizing themselves with the information provided in the MSDS, workers can protect themselves from potential hazards and ensure compliance with safety regulations. Proper storage, handling, and disposal of the additive are crucial for preventing accidents and maintaining a safe work environment. By following the guidelines outlined in the MSDS, workers can effectively use anti-strip asphalt additives to improve the performance and longevity of asphalt pavements.