Table of Contents

فوائد استخدام حبل أسلاك الفولاذ المقاوم للصدأ مقاس 2 مم للتطبيقات الخارجية

كيفية الصيانة والعناية بحبل أسلاك الفولاذ المقاوم للصدأ مقاس 2 مم

فهم IWRC (نواة الحبل السلكي المستقل) في مصطلحات الحبال السلكية

من المهم ملاحظة أنه ليس كل الحبال السلكية تحتوي على قلب IWRC. تحتوي بعض الحبال السلكية على قلب من الألياف، يتكون من ألياف طبيعية أو صناعية، مثل السيزال أو البولي بروبيلين. على الرغم من أن نوى الألياف خفيفة الوزن ومرنة، إلا أنها ليست قوية أو متينة مثل نوى IWRC. تُستخدم نوى الألياف عادةً في التطبيقات التي يكون الوزن فيها مصدر قلق، كما هو الحال في كابلات المصاعد أو الجسور المعلقة.

في الختام، يعد فهم ما يعنيه IWRC بالحبل السلكي أمرًا ضروريًا لاختيار النوع المناسب من الحبال السلكية لتطبيقك. توفر الحبال السلكية ذات قلب IWRC قوة كسر متزايدة ومقاومة أفضل للتآكل والتآكل ومرونة محسنة مقارنة بالحبال السلكية ذات قلوب الألياف. من خلال اختيار حبل سلكي مع IWRC، يمكنك ضمان سلامة وكفاءة تطبيقات الحبال السلكية الخاصة بك.

Understanding IWRC (Independent Wire Rope Core) in Wire Rope Terminology

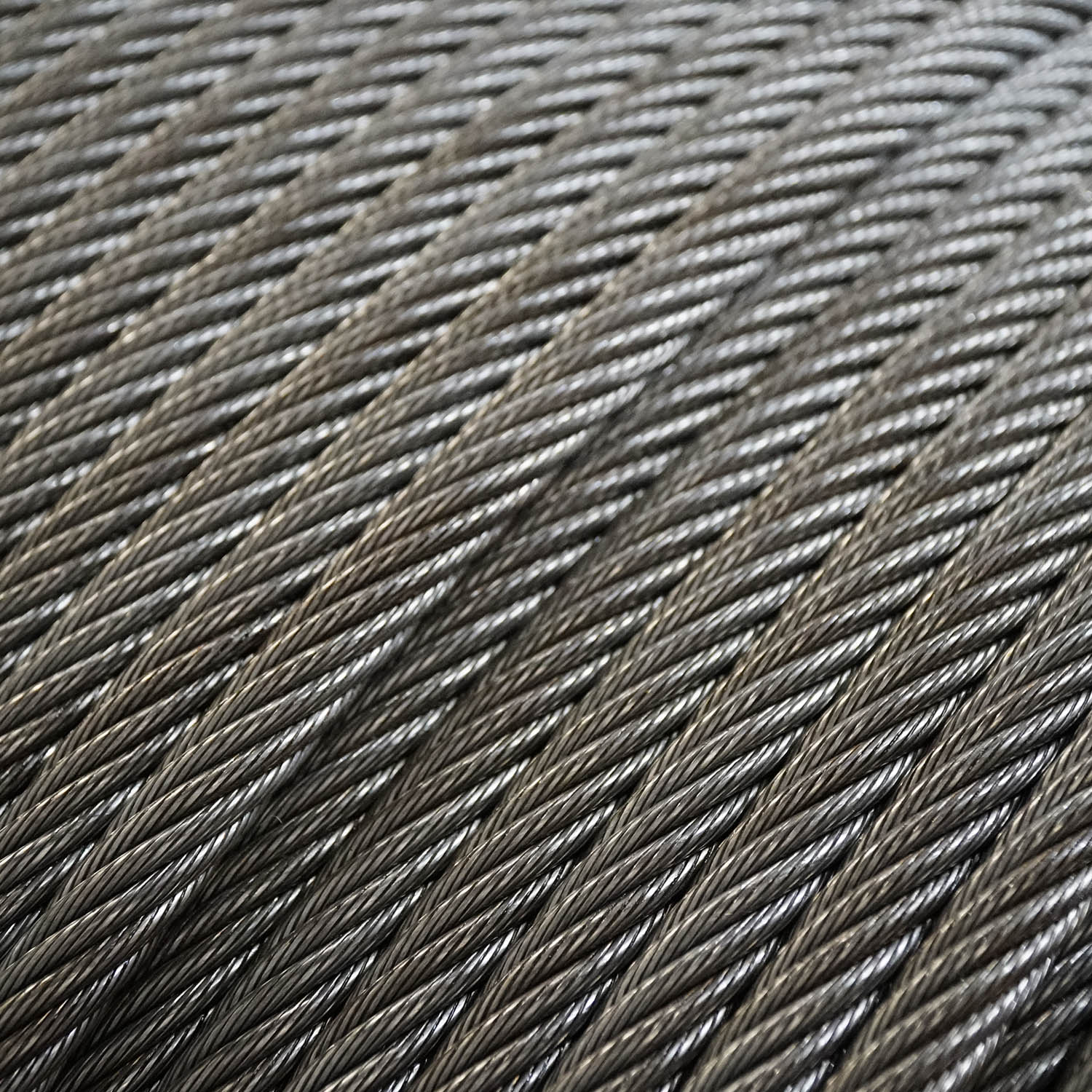

Wire rope is a crucial component in various industries, including construction, mining, and transportation. It is used for lifting heavy loads, securing structures, and providing support in various applications. One important aspect of wire rope terminology is the IWRC, which stands for Independent Wire Rope Core. Understanding what IWRC means in wire rope is essential for ensuring the Safety and efficiency of wire rope applications.

IWRC refers to a type of core construction in wire rope where the core is made up of a separate strand of wire rope. This core strand is independent of the outer strands that make up the wire rope. The purpose of the IWRC is to provide added strength and stability to the wire rope, making it more resistant to crushing, bending, and fatigue.

One of the key benefits of using a wire rope with an IWRC is its increased breaking strength. The independent core strand adds an extra layer of support to the wire rope, allowing it to withstand higher loads without breaking. This is particularly important in applications where heavy loads are being lifted or moved, as the wire rope needs to be able to support the weight without failing.

In addition to increased breaking strength, wire ropes with an IWRC also have better resistance to abrasion and wear. The separate core strand helps to distribute the load more evenly across the wire rope, reducing the risk of damage from friction and other external factors. This can extend the lifespan of the wire rope and reduce the need for frequent replacements, saving time and money in the long run.

Another advantage of using a wire rope with an IWRC is its improved flexibility. The independent core strand allows the wire rope to bend and flex more easily, making it easier to handle and maneuver in tight spaces. This can be especially beneficial in applications where the wire rope needs to be threaded through Pulleys, sheaves, or other equipment with limited clearance.

It is important to note that not all wire ropes have an IWRC core. Some wire ropes have a Fiber core, which is made up of natural or synthetic fibers, such as sisal or polypropylene. While fiber cores are lightweight and flexible, they are not as strong or durable as IWRC cores. Fiber cores are typically used in applications where weight is a concern, such as in Elevator cables or suspension bridges.

In conclusion, understanding what IWRC means in wire rope is essential for selecting the right type of wire rope for your application. Wire ropes with an IWRC core offer increased breaking strength, better resistance to abrasion and wear, and improved flexibility compared to wire ropes with fiber cores. By choosing a wire rope with an IWRC, you can ensure the safety and efficiency of your wire rope applications.