Table of Contents

Benefits of Using API Seamless Steel Casing for Oil Well Drilling

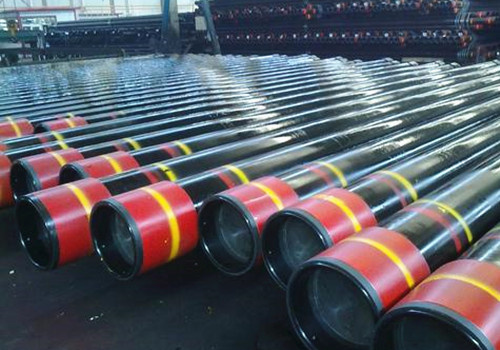

API seamless steel casing is a critical component in oil well drilling operations. It is designed to provide structural support and protection for the wellbore, ensuring the integrity of the well and maximizing production efficiency. API seamless steel casing is manufactured to meet the stringent standards set by the American Petroleum Institute (API), ensuring high quality and reliability in oilfield applications.

One of the key benefits of using API seamless steel casing is its superior strength and durability. The seamless construction of the casing eliminates the risk of weak points or weld defects, providing a strong and reliable barrier against the high pressures and temperatures encountered in oil well drilling. This strength and durability help to prevent casing failures and ensure the long-term integrity of the well, reducing the risk of costly downtime and environmental damage.

In addition to its strength and durability, API seamless steel casing offers excellent corrosion resistance. The casing is typically coated with a protective layer of corrosion-resistant material, such as epoxy or Zinc, to prevent rust and degradation in harsh drilling environments. This corrosion resistance helps to extend the service life of the casing and maintain the integrity of the well over time, reducing maintenance costs and ensuring reliable performance in challenging conditions.

Another benefit of using API seamless steel casing is its versatility and compatibility with a wide range of wellbore configurations. The casing is available in a variety of sizes and grades to accommodate different drilling requirements, allowing for greater flexibility in well design and construction. This versatility makes API seamless steel casing suitable for a wide range of oilfield applications, from conventional vertical wells to complex horizontal and directional wells.

Furthermore, API seamless steel casing is designed to provide a tight seal against the wellbore, preventing fluid migration and maintaining well control during drilling and production operations. The casing is threaded and coupled to create a secure connection that can withstand the high pressures and temperatures encountered in oilfield applications. This tight seal helps to prevent leaks and blowouts, ensuring the Safety of personnel and protecting the Environment from potential contamination.

In conclusion, API seamless steel casing offers a range of benefits for oil well drilling operations. Its superior strength, durability, corrosion resistance, versatility, and tight seal make it an ideal choice for ensuring the integrity and efficiency of oilfield casing. By using API seamless steel casing, operators can minimize the risk of casing failures, reduce maintenance costs, and improve overall well performance. With its high quality and reliability, API seamless steel casing is a trusted solution for high-quality oilfield casing in oil well drilling.

How to Choose the Right API Seamless Steel Casing for High-Quality Oilfield Casing

API seamless steel casing is an essential component in oilfield casing for oil well drilling. It plays a crucial role in protecting the wellbore and ensuring the integrity of the well. Choosing the right API seamless steel casing is essential for high-quality oilfield casing. There are several factors to consider when selecting API seamless steel casing for oil well drilling.

One of the most important factors to consider when choosing API seamless steel casing is the grade of the steel. API grades are standardized by the American Petroleum Institute (API) and are classified based on their mechanical properties. The most common API grades for seamless steel casing are API 5CT J55, API 5CT K55, API 5CT N80, and API 5CT L80. Each grade has its own set of mechanical properties, such as yield strength, tensile strength, and hardness. It is important to select the grade of steel casing that is suitable for the specific drilling conditions and wellbore requirements.

Another important factor to consider when choosing API seamless steel casing is the size and dimensions of the casing. API seamless steel casing is available in a variety of sizes and dimensions to accommodate different wellbore diameters and depths. It is important to select the correct size and dimensions of casing to ensure a proper fit and seal in the wellbore. Improper sizing of casing can Lead to leaks, casing collapse, and other wellbore integrity issues.

In addition to grade and size, it is also important to consider the Thread type and connection of the API seamless steel casing. API casing is typically threaded and coupled to provide a secure connection between casing joints. There are several types of thread connections available, such as API BTC (Buttress Thread and Coupling), API LTC (Long Thread and Coupling), and API STC (Short Thread and Coupling). It is important to select the appropriate thread type and connection for the specific drilling conditions and wellbore requirements.

Furthermore, it is important to consider the corrosion resistance of the API seamless steel casing. Corrosion can occur in oilfield environments due to exposure to corrosive fluids, gases, and high temperatures. API seamless steel casing is typically coated with a corrosion-resistant material, such as epoxy or zinc, to protect against corrosion. It is important to select casing with a high level of corrosion resistance to ensure the longevity and integrity of the wellbore.

In conclusion, choosing the right API seamless steel casing is essential for high-quality oilfield casing in oil well drilling. Factors to consider when selecting API seamless steel casing include grade, size, dimensions, thread type and connection, and corrosion resistance. By carefully considering these factors, oilfield operators can ensure the integrity and longevity of their wellbores.API seamless steel casing is an essential component in oilfield casing for oil well drilling. It plays a crucial role in protecting the wellbore and ensuring the integrity of the well. Choosing the right API seamless steel casing is essential for high-quality oilfield casing. There are several factors to consider when selecting API seamless steel casing for oil well drilling.

One of the most important factors to consider when choosing API seamless steel casing is the grade of the steel. API grades are standardized by the American Petroleum Institute (API) and are classified based on their mechanical properties. The most common API grades for seamless steel casing are API 5CT J55, API 5CT K55, API 5CT N80, and API 5CT L80. Each grade has its own set of mechanical properties, such as yield strength, tensile strength, and hardness. It is important to select the grade of steel casing that is suitable for the specific drilling conditions and wellbore requirements.

Another important factor to consider when choosing API seamless steel casing is the size and dimensions of the casing. API seamless steel casing is available in a variety of sizes and dimensions to accommodate different wellbore diameters and depths. It is important to select the correct size and dimensions of casing to ensure a proper fit and seal in the wellbore. Improper sizing of casing can lead to leaks, casing collapse, and other wellbore integrity issues.

In addition to grade and size, it is also important to consider the thread type and connection of the API seamless steel casing. API casing is typically threaded and coupled to provide a secure connection between casing joints. There are several types of thread connections available, such as API BTC (Buttress Thread and Coupling), API LTC (Long Thread and Coupling), and API STC (Short Thread and Coupling). It is important to select the appropriate thread type and connection for the specific drilling conditions and wellbore requirements.

Furthermore, it is important to consider the corrosion resistance of the API seamless steel casing. Corrosion can occur in oilfield environments due to exposure to corrosive fluids, gases, and high temperatures. API seamless steel casing is typically coated with a corrosion-resistant material, such as epoxy or zinc, to