Table of Contents

Benefits of Using API OCTG Seamless Steel Pipe in Oil and Gas Industry

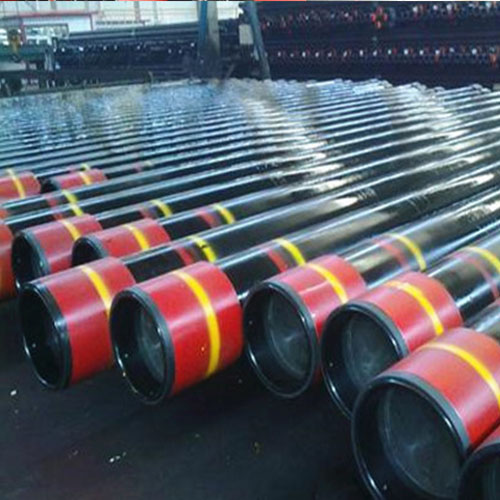

API OCTG seamless steel pipe is a crucial component in the oil and gas industry, playing a vital role in the extraction and transportation of oil and gas from the well to the surface. These pipes are designed to withstand high pressure, corrosive environments, and extreme temperatures, making them ideal for use in the harsh conditions of the oil and gas industry.

One of the key benefits of using API OCTG seamless steel pipe is its superior strength and durability. These pipes are made from high-quality steel that has been specially designed to withstand the demanding conditions of the oil and gas industry. This means that they are less likely to fail or break under pressure, reducing the risk of costly downtime and repairs.

In addition to their strength, API OCTG seamless Steel Pipes are also highly resistant to corrosion. This is essential in the oil and gas industry, where pipes are constantly exposed to corrosive substances such as oil, gas, and saltwater. By using corrosion-resistant pipes, companies can extend the lifespan of their equipment and reduce the risk of leaks and spills.

Another benefit of API OCTG seamless steel pipes is their versatility. These pipes come in a variety of sizes and specifications, making them suitable for a wide range of applications in the oil and gas industry. Whether you need a casing pipe, tubing pipe, or drill pipe, there is an API OCTG seamless steel pipe that meets your requirements.

https://www.youtube.com/watch?v=5tqzxNlncw4Furthermore, API OCTG seamless steel pipes are easy to install and maintain. Their seamless design eliminates the need for welding, reducing the risk of weak points and leaks. This not only saves time and money during installation but also makes maintenance and repairs easier and more cost-effective.

Moreover, API OCTG seamless steel pipes are designed to meet strict industry standards set by the American Petroleum Institute (API). This ensures that the pipes are of the highest quality and meet the necessary Safety and performance requirements for use in the oil and gas industry. By using API-certified pipes, companies can have peace of mind knowing that their equipment is reliable and compliant with industry regulations.

In conclusion, API OCTG seamless steel pipes offer a wide range of benefits for the oil and gas industry. From their superior strength and durability to their corrosion resistance and versatility, these pipes are essential for the safe and efficient extraction and transportation of oil and gas. By using API OCTG seamless steel pipes, companies can reduce the risk of equipment failure, extend the lifespan of their equipment, and ensure compliance with industry standards.

Comparison of BTC, LTC, and STC Connections for Tubing and Casing Pipes

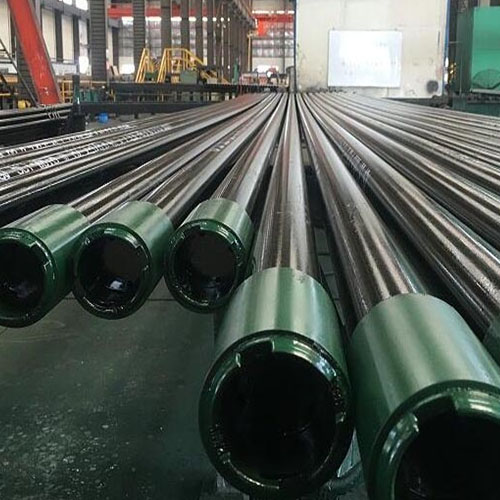

API OCTG seamless steel pipe casing pipe tubing pipe BTC LTC STC tube are all types of connections used in the oil and gas industry for tubing and casing pipes. These connections play a crucial role in ensuring the integrity and efficiency of the wellbore. In this article, we will compare BTC, LTC, and STC connections to help you understand their differences and applications.

BTC, which stands for Buttress Thread Casing, is a type of connection commonly used in casing pipes. It features a tapered thread with a 60-degree thread form and a flat crest. This design allows for easy makeup and breakout of the connection, making it ideal for applications where frequent assembly and disassembly are required. BTC connections are known for their high torque capacity and resistance to galling, making them suitable for high-pressure and high-temperature environments.

LTC, or Long Thread Casing, is another type of connection used in casing pipes. LTC connections have a longer thread length compared to BTC connections, providing a larger contact area between the threads. This results in improved load-carrying capacity and better sealing performance. LTC connections are commonly used in applications where high axial loads and bending stresses are expected, such as deepwater drilling and horizontal wells.

STC, or Short Thread Casing, is a type of connection that is similar to LTC but with a shorter thread length. STC connections are designed for applications where space constraints or weight limitations are a concern. Despite their shorter thread length, STC connections still offer good load-carrying capacity and sealing performance. They are commonly used in shallow wells or applications where the casing string needs to be lightweight.

When comparing BTC, LTC, and STC connections, it is important to consider factors such as torque capacity, load-carrying capacity, sealing performance, and ease of makeup and breakout. BTC connections are known for their high torque capacity and resistance to galling, making them suitable for high-pressure and high-temperature environments. LTC connections offer improved load-carrying capacity and sealing performance, making them ideal for applications with high axial loads and bending stresses. STC connections are designed for applications where space constraints or weight limitations are a concern, offering good load-carrying capacity and sealing performance despite their shorter thread length.

In conclusion, BTC, LTC, and STC connections are all important types of connections used in the oil and gas industry for tubing and casing pipes. Each type of connection has its own unique characteristics and applications, making it important to choose the right connection based on the specific requirements of the wellbore. By understanding the differences between BTC, LTC, and STC connections, you can make informed decisions when selecting the appropriate connection for your drilling operation.