Table of Contents

Benefits of Using API 5L Seamless Steel Pipes in Petroleum Pipeline Construction

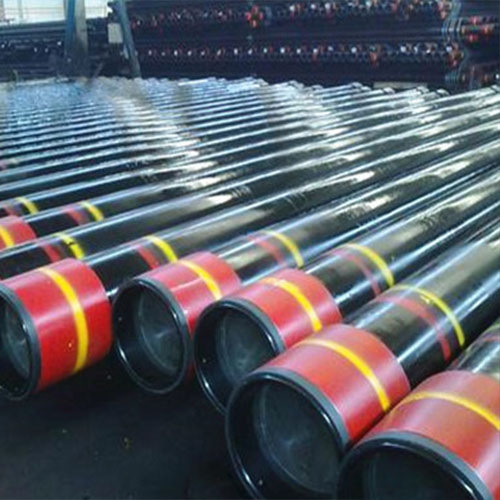

API 5L seamless steel pipes are widely used in the construction of petroleum pipelines due to their numerous benefits. These pipes are made from high-quality Carbon Steel, making them strong, durable, and resistant to corrosion. The seamless design of these pipes ensures a smooth flow of oil and gas, reducing the risk of leaks and ensuring the safe transportation of petroleum products.

One of the key benefits of using API 5L seamless steel pipes in petroleum pipeline construction is their high tensile strength. These pipes can withstand high pressure and temperature conditions, making them ideal for Transporting oil and gas over long distances. Additionally, their seamless design eliminates the need for welding, which can weaken the structure of the pipeline and increase the risk of leaks.

Another advantage of API 5L seamless steel pipes is their resistance to corrosion. Petroleum products can be highly corrosive, especially when transported at high temperatures and pressures. The carbon steel used in these pipes is specially treated to resist corrosion, ensuring the longevity of the pipeline and reducing maintenance costs over time.

In addition to their strength and corrosion resistance, API 5L seamless steel pipes are also highly flexible. This flexibility allows for easy installation and maintenance of the pipeline, reducing construction time and costs. The seamless design of these pipes also ensures a tight seal, preventing leaks and minimizing the risk of environmental contamination.

Furthermore, API 5L seamless steel pipes are available in a variety of sizes and thicknesses, making them suitable for a wide range of applications. Whether you are constructing a small oil pipeline or a large-scale petroleum distribution network, these pipes can be customized to meet your specific requirements. This versatility makes API 5L seamless steel pipes a popular choice among engineers and contractors in the petroleum industry.

In conclusion, API 5L seamless steel pipes offer numerous benefits for petroleum pipeline construction. Their high tensile strength, corrosion resistance, flexibility, and versatility make them an ideal choice for transporting oil and gas safely and efficiently. By using these pipes in your next pipeline project, you can ensure the reliability and longevity of your infrastructure while minimizing maintenance costs and environmental risks.

How to Ensure Quality and Compliance When Using API 5L Seamless Steel Pipes for Carbon Oil Casing Applications

API 5L seamless steel pipes are widely used in the petroleum industry for various applications, including carbon oil casing. These pipes are known for their high strength, durability, and resistance to corrosion, making them an ideal choice for transporting oil and gas in harsh environments. However, ensuring the quality and compliance of API 5L seamless steel pipes is crucial to prevent any potential Safety hazards and ensure the efficient operation of the pipeline.

One of the key factors to consider when using API 5L seamless steel pipes for carbon oil casing applications is the material composition. These pipes are typically made from carbon steel, which is known for its high tensile strength and ability to withstand high temperatures and pressures. It is important to ensure that the material used in the pipes meets the specifications outlined in the API 5L standard to guarantee their performance and longevity.

In addition to material composition, the manufacturing process of API 5L seamless steel pipes also plays a crucial role in determining their quality. These pipes are produced using a seamless manufacturing process, which involves heating a solid steel billet and then shaping it into a cylindrical form without any seams. This seamless construction helps to eliminate weak points in the pipe, making it more resistant to leaks and failures.

To ensure the quality and compliance of API 5L seamless steel pipes, it is essential to conduct thorough inspections and testing throughout the manufacturing process. This includes checking the dimensions, chemical composition, and mechanical properties of the pipes to ensure they meet the requirements of the API 5L standard. Additionally, non-destructive testing methods such as ultrasonic testing and magnetic particle inspection can be used to detect any defects or imperfections in the pipes.

Once the API 5L seamless steel pipes have been manufactured and tested, it is important to handle and transport them properly to prevent any damage or contamination. These pipes should be stored in a clean, dry Environment away from any corrosive substances or contaminants that could compromise their integrity. Proper handling and storage practices will help to ensure that the pipes remain in good condition until they are installed in the oil casing application.

When installing API 5L seamless steel pipes for carbon oil casing applications, it is important to follow the guidelines outlined in the API 5L standard to ensure proper installation and operation. This includes using the correct welding procedures, fittings, and connections to prevent any leaks or failures in the pipeline. It is also important to conduct regular inspections and maintenance of the pipeline to identify any potential issues and address them promptly.

In conclusion, API 5L seamless steel pipes are a reliable and durable choice for carbon oil casing applications in the petroleum industry. By ensuring the quality and compliance of these pipes through proper material selection, manufacturing processes, testing, handling, and installation practices, you can help to prevent safety hazards and ensure the efficient operation of the pipeline. Following the guidelines outlined in the API 5L standard will help to guarantee the performance and longevity of the pipes, ultimately leading to a successful and reliable oil casing application.

https://www.youtube.com/watch?v=uatADWnrH-8