Table of Contents

Benefits of Using API 5CT J55 K55 Seamless Casing Tubing

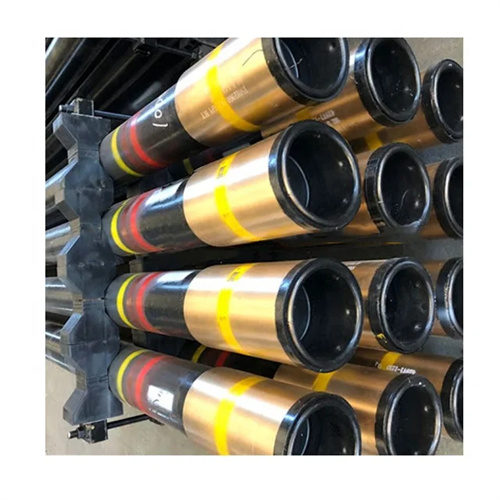

API 5CT J55 K55 Seamless Casing Tubing is a popular choice in the oil and gas industry for its durability and reliability. This type of tubing is made from high-quality steel and is designed to withstand the harsh conditions of drilling and extraction operations. In this article, we will discuss the benefits of using API 5CT J55 K55 Seamless Casing Tubing and why it is a preferred choice for many companies in the industry.

One of the main benefits of using API 5CT J55 K55 Seamless Casing Tubing is its strength and durability. This type of tubing is made from high-quality steel that is designed to withstand high pressure and extreme temperatures. This makes it ideal for use in drilling and extraction operations where the tubing is subjected to harsh conditions. The seamless design of the tubing also helps to prevent leaks and failures, ensuring that the operation runs smoothly and efficiently.

Another benefit of using API 5CT J55 K55 Seamless Casing Tubing is its versatility. This type of tubing can be used in a variety of applications, including drilling, extraction, and production. It is available in a range of sizes and lengths, making it easy to customize to fit the specific needs of the operation. This versatility makes API 5CT J55 K55 Seamless Casing Tubing a cost-effective choice for many companies in the industry.

In addition to its strength and versatility, API 5CT J55 K55 Seamless Casing Tubing is also known for its corrosion resistance. The high-quality steel used in the tubing is designed to resist corrosion and rust, even in the harshest environments. This helps to extend the life of the tubing and reduce the need for maintenance and repairs, saving companies time and money in the long run.

Furthermore, API 5CT J55 K55 Seamless Casing Tubing is easy to install and maintain. The seamless design of the tubing makes it easy to connect and disconnect, reducing downtime and increasing efficiency. This ease of installation also helps to reduce labor costs and minimize the risk of errors during the installation process. Additionally, the corrosion-resistant properties of the tubing help to reduce the need for maintenance, further saving companies time and money.

Overall, API 5CT J55 K55 Seamless Casing Tubing offers a range of benefits that make it a preferred choice for many companies in the oil and gas industry. Its strength, durability, versatility, and corrosion resistance make it an ideal option for drilling, extraction, and production operations. Additionally, its ease of installation and maintenance help to reduce costs and increase efficiency. If you are looking for a reliable and cost-effective tubing option for your operation, consider using API 5CT J55 K55 Seamless Casing Tubing.

Comparison of API 5CT J55 and K55 Seamless Casing Tubing

API 5CT J55 and K55 seamless casing tubing are two common types of seamless casing tubing used in the oil and gas industry. Both J55 and K55 are grades of steel that are specified in the American Petroleum Institute (API) 5CT standard. While they have some similarities, there are also key differences between the two grades that are important to consider when selecting the appropriate casing tubing for a particular application.

One of the main differences between API 5CT J55 and K55 seamless casing tubing is their chemical composition. J55 has a higher carbon content than K55, which gives it slightly better mechanical properties, such as higher tensile strength and yield strength. On the other hand, K55 has a lower carbon content, which makes it more suitable for sour service applications where the casing tubing will be exposed to corrosive environments.

In terms of mechanical properties, both J55 and K55 seamless casing tubing have similar minimum yield strengths and maximum tensile strengths. However, J55 has a slightly higher minimum yield strength than K55, which can make it more suitable for applications where higher strength is required. Additionally, J55 has a higher impact toughness than K55, which can be important in applications where the casing tubing may be subjected to high-stress conditions.

Another important factor to consider when comparing API 5CT J55 and K55 seamless casing tubing is their manufacturing process. J55 is typically produced using a hot rolling process, which results in a more uniform Grain structure and better overall quality. K55, on the other hand, is often produced using a cold drawing process, which can result in a slightly lower quality product. However, both grades of casing tubing are manufactured to meet the stringent requirements of the API 5CT standard, so the differences in manufacturing process may not be significant in practice.

When it comes to cost, there is typically little difference between API 5CT J55 and K55 seamless casing tubing. Both grades are widely available from a variety of manufacturers, so pricing is usually competitive. However, it is important to consider the overall quality and performance of the casing tubing when making a purchasing decision, rather than just focusing on cost alone.

In conclusion, API 5CT J55 and K55 seamless casing tubing are two common grades of steel used in the oil and gas industry. While they have some similarities in terms of mechanical properties and manufacturing process, there are also key differences that can impact their suitability for different applications. When selecting between J55 and K55 casing tubing, it is important to consider factors such as chemical composition, mechanical properties, manufacturing process, and cost to ensure that the right grade is chosen for the specific requirements of the project. Ultimately, both J55 and K55 are high-quality grades of casing tubing that meet the stringent requirements of the API 5CT standard and are suitable for a wide range of applications in the oil and gas industry.