Table of Contents

Benefits of Using Asphalt Bonding Agents in Pavement Construction

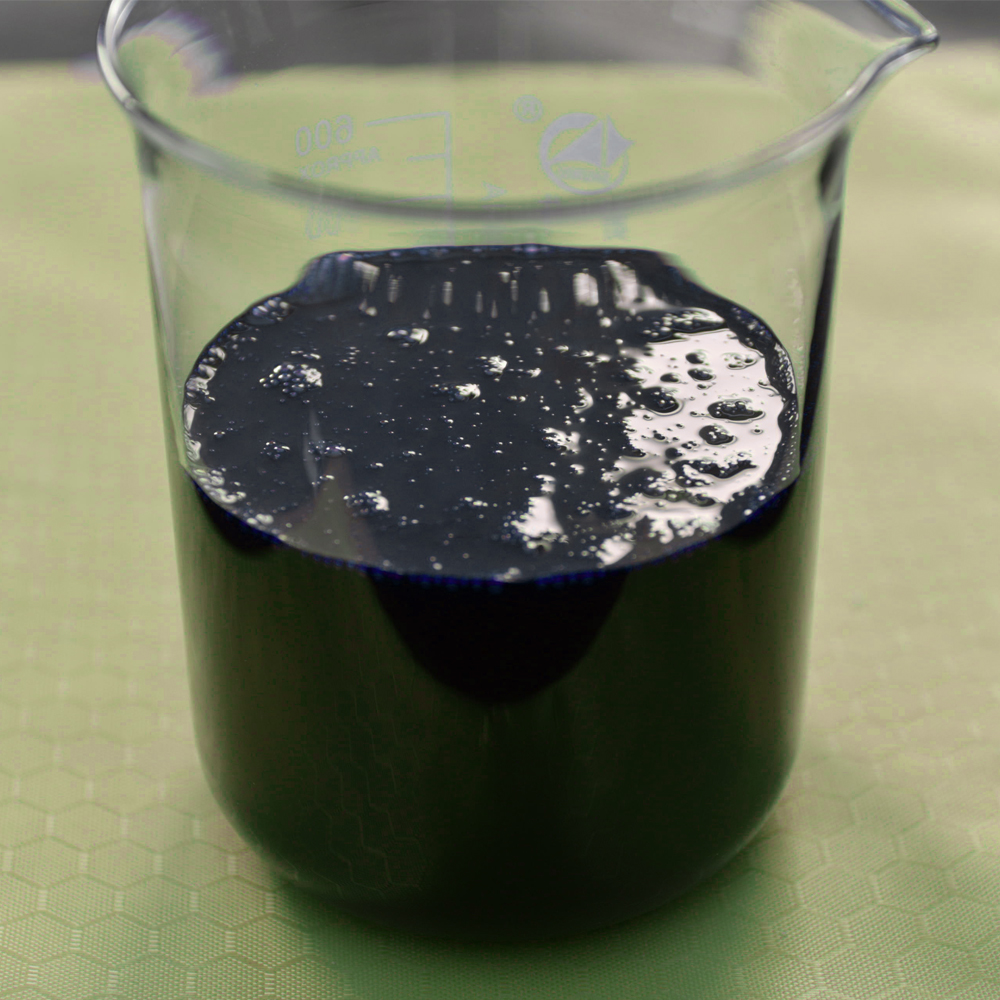

Asphalt bonding agents play a crucial role in pavement construction, providing a strong and durable bond between layers of asphalt. Understanding the lifecycle of these bonding agents is essential for ensuring the longevity and performance of the pavement.

The lifecycle of asphalt bonding agents begins with the application of the agent to the existing pavement surface. This initial step is critical for ensuring proper adhesion between the old and new asphalt layers. The bonding agent penetrates the surface of the existing pavement, creating a strong bond that helps prevent delamination and cracking.

Once the bonding agent has been applied, the new asphalt layer is placed on top. The bonding agent acts as a bridge between the old and new layers, ensuring that they adhere together effectively. This bond is essential for maintaining the structural integrity of the pavement and preventing premature failure.

Over time, the bonding agent undergoes a process of aging and degradation. Exposure to sunlight, moisture, and traffic can cause the bonding agent to break Down, reducing its effectiveness. As the bonding agent deteriorates, the bond between the asphalt layers weakens, increasing the risk of delamination and other pavement issues.

Regular maintenance and inspection are essential for monitoring the condition of the bonding agent and addressing any issues that may arise. Cracks, potholes, and other signs of deterioration should be repaired promptly to prevent further damage to the pavement. In some cases, it may be necessary to reapply the bonding agent to restore the bond between the asphalt layers.

Proper application and maintenance of asphalt bonding agents can extend the lifecycle of the pavement and reduce the need for costly repairs. By ensuring that the bonding agent remains in good condition, pavement owners can maximize the performance and longevity of their asphalt surfaces.

In addition to improving the bond between asphalt layers, bonding agents offer a range of other benefits for pavement construction. These agents help reduce the risk of reflective cracking, which occurs when cracks in the underlying pavement surface are transferred to the new asphalt layer. By providing a strong bond between layers, bonding agents help prevent cracks from propagating through the pavement, extending its lifespan.

Bonding agents also help improve the overall performance of the pavement by enhancing its resistance to moisture and other environmental factors. By sealing the surface of the pavement, bonding agents help prevent water infiltration, reducing the risk of damage from freeze-thaw cycles and other weather-related issues.

Overall, understanding the lifecycle of asphalt bonding agents is essential for ensuring the longevity and performance of pavement surfaces. By properly applying and maintaining these agents, pavement owners can maximize the lifespan of their asphalt surfaces and reduce the need for costly repairs. Bonding agents play a critical role in pavement construction, providing a strong and durable bond between layers of asphalt that helps maintain the structural integrity of the pavement.

Factors Affecting the Durability of Asphalt Bonding Agents in Different Environmental Conditions

Asphalt bonding agents play a crucial role in the construction and maintenance of roads, driveways, and other paved surfaces. These agents are used to improve the adhesion between layers of asphalt, ensuring a strong and durable pavement structure. However, the durability of asphalt bonding agents can be affected by various factors, including environmental conditions. Understanding how these factors impact the lifecycle of asphalt bonding agents is essential for ensuring the longevity and performance of paved surfaces.

One of the key factors that can affect the durability of asphalt bonding agents is temperature. Extreme temperatures, both hot and cold, can have a significant impact on the performance of these agents. In hot weather, asphalt bonding agents may soften and lose their adhesive properties, leading to poor adhesion between layers of asphalt. On the other hand, in cold weather, these agents may become brittle and prone to cracking, compromising the integrity of the pavement structure. It is important to consider the temperature range in which the asphalt bonding agent will be used and select a product that is suitable for the specific climate conditions.

Another factor that can affect the durability of asphalt bonding agents is moisture. Water can seep into the pavement structure and weaken the bond between layers of asphalt, leading to delamination and premature pavement failure. It is important to ensure that the surface is properly prepared and free of moisture before applying the bonding agent. Additionally, using a waterproofing additive in the bonding agent can help protect the pavement structure from water infiltration and improve its durability in wet conditions.

In addition to temperature and moisture, the type of traffic and load that the pavement will be subjected to can also impact the durability of asphalt bonding agents. Heavy traffic and frequent heavy loads can put a strain on the pavement structure, causing the bonding agent to deteriorate more quickly. It is important to select a bonding agent that is designed to withstand the specific traffic and load conditions of the pavement to ensure its longevity and performance.

Furthermore, exposure to UV radiation can also affect the durability of asphalt bonding agents. UV rays can break down the chemical bonds in the bonding agent, causing it to degrade and lose its adhesive properties. To protect the bonding agent from UV damage, it is important to apply a UV-resistant coating or sealer over the pavement surface. This will help prolong the life of the bonding agent and maintain the integrity of the pavement structure.

| No. | Product Name |

| 1 | Stripping inhibitor |

In conclusion, the durability of asphalt bonding agents can be affected by various factors, including temperature, moisture, traffic, and UV radiation. Understanding how these factors impact the lifecycle of bonding agents is essential for ensuring the longevity and performance of paved surfaces. By selecting a bonding agent that is suitable for the specific environmental conditions and taking steps to protect it from damage, you can help extend the life of your pavement and reduce the need for costly repairs and maintenance.