Table of Contents

Benefits of Using Carbon Steel Pipe ASME53 in Industrial Applications

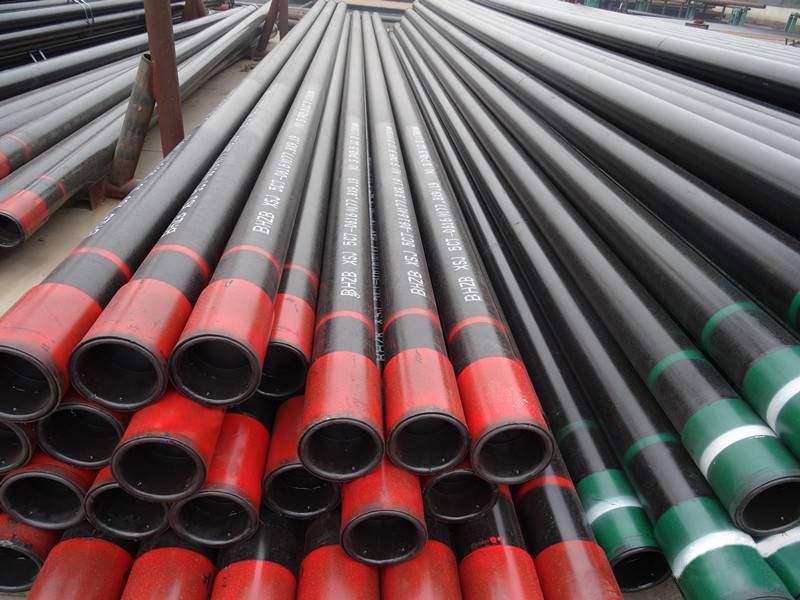

Carbon Steel Pipes are a popular choice in various industrial applications due to their durability, strength, and versatility. One particular type of carbon steel pipe that stands out is the ASME53 custom size steel seamless tube. This precision cold drawn tube offers numerous benefits that make it a preferred option for many industries.

One of the key advantages of using ASME53 carbon steel pipes is their high strength-to-weight ratio. This means that they can withstand heavy loads and high pressures without being too bulky or cumbersome. This makes them ideal for applications where space is limited or where weight restrictions are a concern.

In addition to their strength, ASME53 carbon steel pipes are also known for their excellent corrosion resistance. This is particularly important in industrial settings where pipes are exposed to harsh Chemicals, high temperatures, or corrosive environments. The protective Oxide layer that forms on the surface of carbon steel pipes helps prevent rust and corrosion, extending the lifespan of the pipes and reducing maintenance costs.

Another benefit of ASME53 carbon steel pipes is their versatility. These pipes can be customized to meet specific size and shape requirements, making them suitable for a wide range of applications. Whether you need a straight seam carbon steel welded pipe or a precision cold drawn tube, ASME53 carbon steel pipes can be tailored to your exact specifications.

Furthermore, ASME53 carbon steel pipes are easy to install and maintain. Their seamless design eliminates the need for welding, reducing the risk of leaks and ensuring a tight, secure fit. Additionally, carbon steel pipes are easy to clean and sanitize, making them ideal for industries where hygiene is a priority.

In terms of cost-effectiveness, ASME53 carbon steel pipes offer excellent value for money. Their long lifespan and low maintenance requirements mean that they can provide reliable performance for years to come, saving you time and money on repairs and replacements. Additionally, the high availability of carbon steel pipes in the market makes them a cost-effective option for many industrial applications.

Overall, ASME53 carbon steel pipes are a reliable and versatile choice for a wide range of industrial applications. Their strength, corrosion resistance, and customization options make them ideal for use in demanding environments where performance and durability are key. Whether you need a precision cold drawn tube or a straight seam carbon steel welded pipe, ASME53 carbon steel pipes can meet your needs with ease. With their high strength-to-weight ratio, excellent corrosion resistance, and cost-effectiveness, ASME53 carbon steel pipes are a smart investment for any industrial project.

Comparison Between Custom Size Steel Seamless Tube and Ordinary Straight Seam Carbon Steel Welded Steel Pipes

Carbon steel pipes are a crucial component in various industries, including construction, oil and gas, and manufacturing. When it comes to choosing the right type of carbon steel pipe for a specific application, two common options are custom size steel seamless tubes and ordinary straight seam carbon steel welded pipes. Both types have their own unique characteristics and advantages, which we will explore in this article.

Custom size steel seamless tubes are manufactured by piercing a solid billet of steel to create a hollow tube without any seams. This process results in a smooth and uniform surface finish, making seamless tubes ideal for applications that require high pressure, high temperature, or corrosive environments. The absence of seams also eliminates the risk of weak points in the pipe, reducing the likelihood of leaks or failures.

On the other hand, ordinary straight seam carbon steel welded pipes are made by welding together two pieces of steel along a straight seam. While welded pipes are generally less expensive to produce than seamless tubes, they may have a rougher surface finish and are more prone to corrosion at the weld seam. However, advancements in welding technology have improved the quality of welded pipes, making them suitable for a wide range of applications.

One of the key differences between custom size steel seamless tubes and ordinary straight seam carbon steel welded pipes is their manufacturing process. Seamless tubes are produced by hot or cold drawing a solid steel billet through a die to create the desired shape and size. This process results in a uniform Grain structure and consistent mechanical properties throughout the tube. In contrast, welded pipes are made by joining two pieces of steel using a welding process, which can introduce heat-affected zones and changes in the material properties near the weld seam.

https://www.youtube.com/watch?v=Td4fDAePFrw

In terms of strength and durability, both custom size steel seamless tubes and ordinary straight seam carbon steel welded pipes can meet the requirements of most applications. Seamless tubes are known for their high tensile strength and resistance to internal pressure, making them suitable for critical applications such as oil and gas pipelines. Welded pipes, on the other hand, may have slightly lower tensile strength due to the presence of the weld seam, but they can still provide adequate strength for many applications.

When it comes to cost, welded pipes are generally more affordable than seamless tubes due to the simpler manufacturing process. However, the overall cost of a carbon steel pipe will depend on factors such as size, wall thickness, and material grade. In some cases, the higher initial cost of seamless tubes may be justified by their superior performance and longer service life.

In conclusion, both custom size steel seamless tubes and ordinary straight seam carbon steel welded pipes have their own advantages and limitations. The choice between the two will depend on the specific requirements of the application, including pressure, temperature, corrosion resistance, and budget. Ultimately, it is important to carefully consider these factors and consult with a knowledgeable supplier to select the right type of carbon steel pipe for your project.