Table of Contents

Benefits of Using Butt Welded Seamless Pipe in Industrial Applications

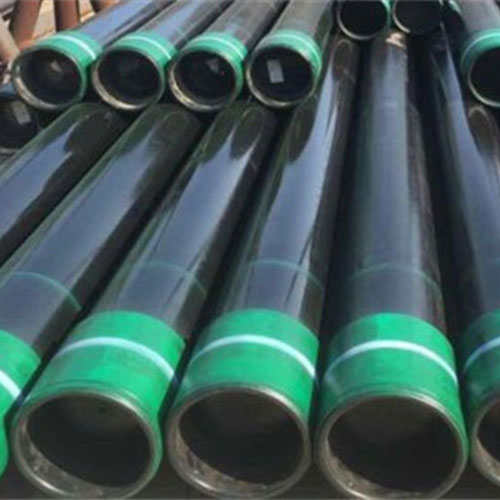

Butt welded seamless pipes are a popular choice in various industrial applications due to their numerous benefits. These pipes are made from high-quality Carbon Steel, such as ASTM A106, ASTM A53, API 5L Gr. B, DIN17175, and DIN1629, which ensures their durability and reliability in demanding environments.

One of the key advantages of butt welded seamless pipes is their superior strength. The seamless construction of these pipes eliminates the weak points that are often found in welded pipes, making them less susceptible to leaks and failures. This strength is crucial in industrial settings where the pipes are subjected to high pressure and temperature conditions.

In addition to their strength, butt welded seamless pipes offer excellent corrosion resistance. The seamless construction of these pipes prevents the formation of corrosion-prone areas, such as weld seams, which can weaken the pipe over time. This corrosion resistance is essential in industries where the pipes come into contact with corrosive substances or environments.

Furthermore, butt welded seamless pipes provide a smooth interior surface, which allows for efficient flow of fluids and gases. The absence of weld seams and other imperfections in the pipe’s interior reduces friction and turbulence, resulting in lower pressure drop and energy consumption. This smooth surface also minimizes the risk of Clogs and blockages, ensuring uninterrupted flow in industrial processes.

Another benefit of using butt welded seamless pipes is their versatility. These pipes can be easily customized to meet specific requirements, such as size, thickness, and material grade. This flexibility makes them suitable for a wide range of applications, from oil and gas pipelines to chemical processing plants.

Moreover, butt welded seamless pipes are easy to install and maintain. The seamless construction of these pipes eliminates the need for complex welding procedures, reducing installation time and costs. Additionally, their smooth interior surface makes them easy to clean and inspect, ensuring long-term performance and reliability.

https://www.youtube.com/watch?v=kcGBRz7l738

In conclusion, butt welded seamless pipes offer numerous benefits that make them an ideal choice for industrial applications. Their superior strength, corrosion resistance, smooth interior surface, versatility, and ease of installation and maintenance make them a reliable and cost-effective solution for various industries. Whether you are looking for a durable pipe for high-pressure applications or a corrosion-resistant pipe for harsh environments, butt welded seamless pipes are a reliable choice that will meet your needs.

Comparison of ASTM A106, ASTM A53, API 5L Gr. B, DIN17175, and DIN1629 Carbon Steel Pipe for 14 Inch Diameter

Butt welded seamless pipes are a popular choice in various industries due to their durability and strength. When it comes to selecting the right carbon steel pipe for a specific project, it is essential to consider the various standards and specifications available in the market. In this article, we will compare the ASTM A106, ASTM A53, API 5L Gr. B, DIN17175, and DIN1629 carbon Steel Pipes for a 14-inch diameter.

ASTM A106 is a standard specification for seamless carbon steel pipe for high-temperature service. It is commonly used in refineries, power plants, and Boilers due to its ability to withstand high temperatures and pressures. ASTM A106 pipes are manufactured using the hot-finished or cold-drawn process, resulting in a seamless and uniform product. These pipes are suitable for bending, flanging, and similar forming operations.

On the other hand, ASTM A53 is a standard specification for welded and seamless carbon steel pipe. It is commonly used in structural applications, such as construction and infrastructure projects. ASTM A53 pipes are available in three types \\u2013 Type F (furnace-welded), Type E (electric-resistance-welded), and Type S (seamless). Type S pipes are preferred for high-pressure applications, while Type E and Type F pipes are suitable for general applications.

API 5L Gr. B is a standard specification for seamless and welded steel line pipe. It is commonly used in the transportation of oil and gas, as well as in the construction of pipelines. API 5L Gr. B pipes are manufactured using the hot-finished or cold-drawn process, similar to ASTM A106 pipes. These pipes are available in various grades, with Grade B being the most commonly used for general applications.

DIN17175 is a standard specification for seamless circular tubes of non-Alloy Steel with specified elevated temperature properties. It is commonly used in the manufacturing of boilers, Heat Exchangers, and Pressure Vessels. DIN17175 pipes are manufactured using the hot-finished process, resulting in a seamless and uniform product. These pipes are suitable for high-temperature applications and are known for their excellent thermal conductivity.

Lastly, DIN1629 is a standard specification for seamless circular tubes of non-alloy steel with special quality requirements. It is commonly used in the manufacturing of mechanical and structural components. DIN1629 pipes are manufactured using the hot-finished process, similar to DIN17175 pipes. These pipes are suitable for bending, flanging, and similar forming operations.

In conclusion, when selecting a carbon steel pipe for a 14-inch diameter, it is essential to consider the specific requirements of the project. ASTM A106, ASTM A53, API 5L Gr. B, DIN17175, and DIN1629 pipes all have their unique characteristics and applications. By understanding the differences between these standards and specifications, you can make an informed decision on the most suitable pipe for your project.