Table of Contents

Benefits of Using Coiled Tubing in Oil and Gas Production

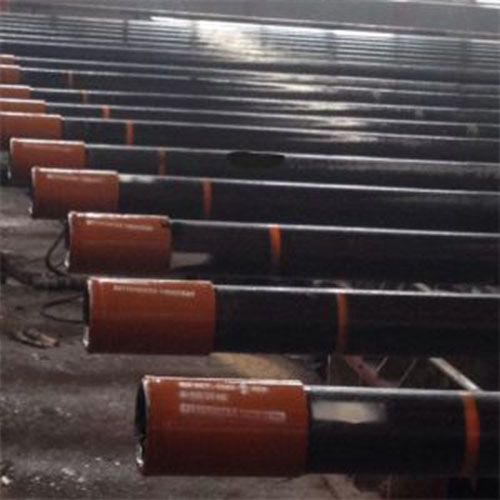

Coiled tubing technology has revolutionized the oil and gas industry by providing a cost-effective and efficient method for well intervention and production. This innovative technique involves the use of a continuous length of tubing wound on a spool, which is inserted into the wellbore to perform various operations such as cleanouts, stimulation, and logging. The benefits of using coiled tubing in oil and gas production are numerous, making it a preferred choice for operators looking to maximize production and minimize downtime.

One of the key advantages of coiled tubing is its ability to reach greater depths in the wellbore compared to conventional tubing. The continuous length of tubing allows for longer reach, enabling operators to access hard-to-reach areas of the wellbore without the need for multiple trips. This not only saves time but also reduces the risk of damage to the wellbore, resulting in increased efficiency and cost savings.

In addition to its extended reach, coiled tubing offers greater flexibility and maneuverability, making it ideal for performing a wide range of operations in the wellbore. The ability to navigate through tight spaces and around Obstacles allows operators to carry out tasks such as cleanouts, acidizing, and fracturing with precision and accuracy. This level of control is essential for optimizing production and ensuring the longevity of the well.

Another benefit of using coiled tubing is its ability to perform multiple operations in a single trip, reducing the need for costly and time-consuming workovers. By combining tasks such as cleanouts, logging, and stimulation into one operation, operators can maximize production and minimize downtime, ultimately increasing profitability. This streamlined approach to well intervention not only saves time and money but also reduces the environmental impact of oil and gas production.

Furthermore, coiled tubing technology is well-suited for use in deviated and horizontal wells, where traditional methods may be impractical or ineffective. The flexibility and reach of coiled tubing allow operators to access these challenging wellbore configurations with ease, enabling them to perform interventions and production enhancement activities with precision and efficiency. This versatility makes coiled tubing an invaluable tool for operators looking to maximize recovery from unconventional reservoirs.

Overall, the benefits of using coiled tubing in oil and gas production are clear. From its extended reach and flexibility to its ability to perform multiple operations in a single trip, coiled tubing offers a cost-effective and efficient solution for well intervention and production enhancement. By leveraging this innovative technology, operators can optimize production, minimize downtime, and maximize profitability, making coiled tubing a valuable asset in the oil and gas industry.