Table of Contents

Welding Stainless Steel: Tips and Techniques

Stainless steel is a popular material in various industries due to its durability, corrosion resistance, and aesthetic appeal. However, welding stainless steel can be a challenging task due to its unique properties. In this article, we will discuss what makes stainless steel weldable, common issues such as wire Rope kinking, and the thinnest Piano wire that can be used for welding.

Stainless steel is a type of steel alloy that contains a minimum of 10.5% chromium, which forms a protective Oxide layer on the surface of the metal. This oxide layer is what gives stainless steel its corrosion resistance. In addition to chromium, stainless steel may also contain other elements such as Nickel, Molybdenum, and Titanium, which further enhance its properties.

When it comes to welding stainless steel, it is important to choose the right type of filler material. The most commonly used filler material for welding stainless steel is ER308L, which is suitable for welding 304 and 304L stainless steels. For welding 316 and 316L stainless steels, ER316L filler material is recommended. It is crucial to match the filler material with the base metal to ensure a strong and durable weld.

Another important factor to consider when welding stainless steel is the welding technique. Stainless steel has a low thermal conductivity, which means that it retains heat for longer periods compared to other metals. This can Lead to distortion and warping of the metal if not properly controlled. To prevent this, it is essential to use a lower heat input and maintain a consistent welding speed.

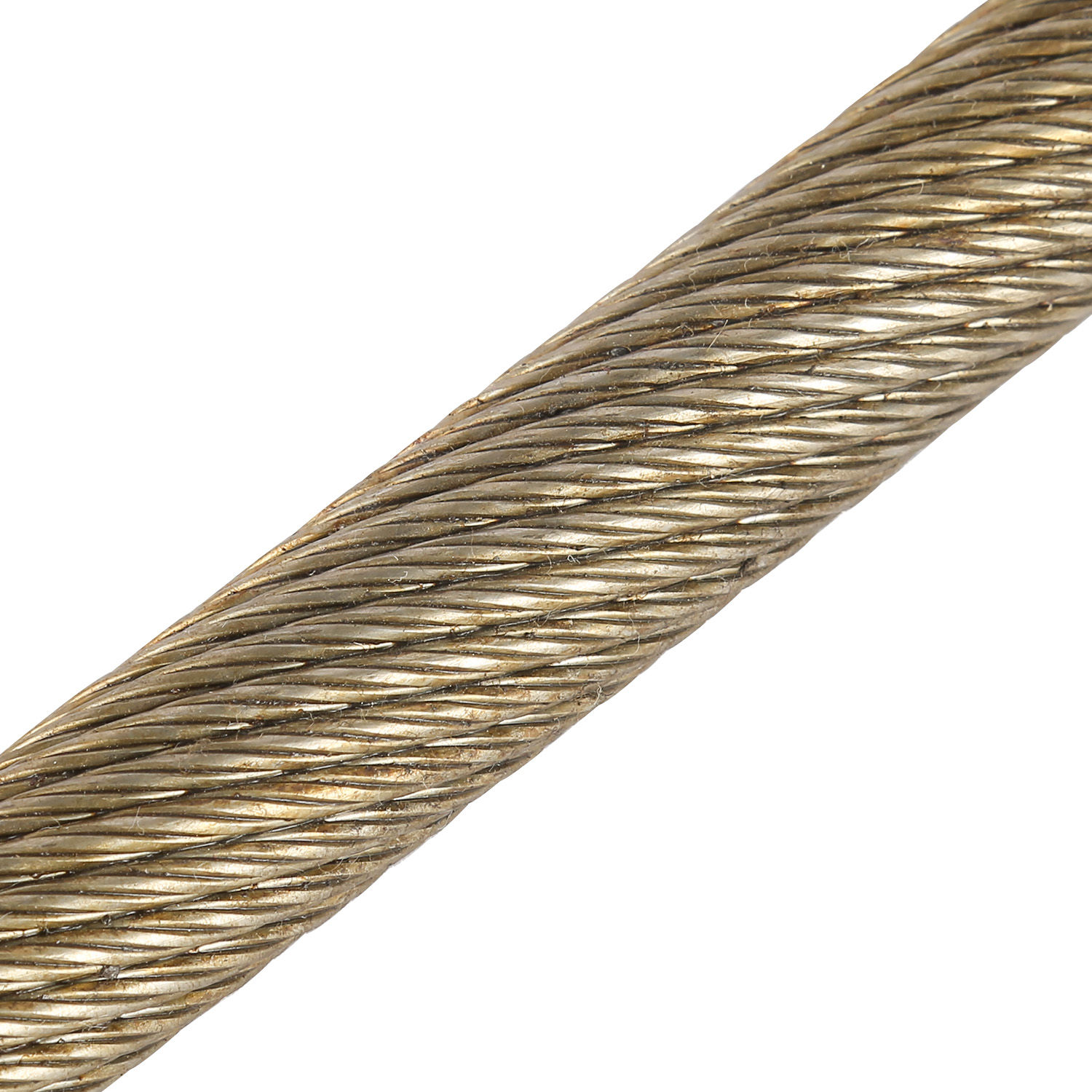

One common issue that welders may encounter when working with stainless steel is wire rope kinking. Wire rope kinking can occur when the wire rope is bent or twisted beyond its minimum bend radius, causing the individual wires to become tangled and deformed. This can weaken the wire rope and compromise its strength. To prevent wire rope kinking, it is important to handle the wire rope carefully and avoid excessive bending or twisting.

In addition to wire rope kinking, another challenge that welders may face when working with stainless steel is finding the thinnest piano wire that can be used for welding. Piano wire is a type of high-Carbon Steel wire that is known for its strength and flexibility. When selecting piano wire for welding stainless steel, it is important to choose a wire that is thin enough to fit into tight spaces but strong enough to withstand the welding process.

Overall, welding stainless steel requires careful consideration of the material properties, filler material, welding technique, and potential challenges such as wire rope kinking. By following the tips and techniques outlined in this article, welders can achieve strong and durable welds on stainless steel components. With the right knowledge and skills, welding stainless steel can be a rewarding and successful endeavor.