Table of Contents

Benefits of Using ASTM A106b/A53b Sch40 Carbon Seamless Steel Pipe in Oil and Gas Well Applications

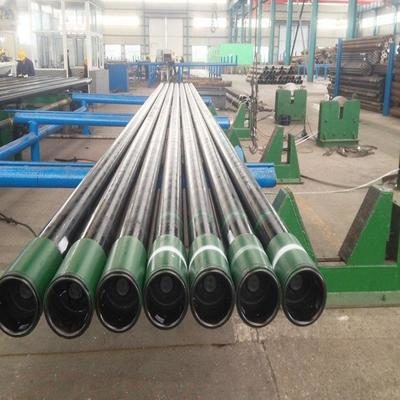

When it comes to the oil and gas industry, the choice of materials for pipelines is crucial. The ASTM A106b/A53b Sch40 carbon seamless steel pipe is a popular choice for many oil and gas well applications due to its numerous benefits. This type of steel pipe is known for its high strength, durability, and resistance to corrosion, making it an ideal choice for Transporting oil and gas in harsh environments.

One of the key benefits of using ASTM A106b/A53b Sch40 carbon seamless steel pipe in oil and gas well applications is its high strength. This type of steel pipe is made from high-quality Carbon Steel, which gives it the strength to withstand high pressure and temperature conditions. This makes it a reliable choice for transporting oil and gas over long distances without the risk of leaks or failures.

In addition to its high strength, ASTM A106b/A53b Sch40 carbon seamless steel pipe is also known for its durability. This type of steel pipe is designed to last for many years, even in the most challenging environments. Its seamless construction eliminates weak points that are common in welded pipes, making it less prone to cracking or failure. This durability ensures that oil and gas can be transported safely and efficiently without the need for frequent repairs or replacements.

Another benefit of using ASTM A106b/A53b Sch40 carbon seamless steel pipe in oil and gas well applications is its resistance to corrosion. The harsh conditions found in oil and gas wells can cause traditional pipes to corrode over time, leading to leaks and contamination of the surrounding Environment. However, carbon seamless steel pipe is highly resistant to corrosion, making it a reliable choice for transporting oil and gas without the risk of environmental damage.

Furthermore, ASTM A106b/A53b Sch40 carbon seamless steel pipe is easy to install and maintain. Its seamless construction allows for quick and efficient installation, reducing downtime and labor costs. Additionally, its low maintenance requirements make it a cost-effective choice for oil and gas companies looking to minimize operational expenses.

In conclusion, the benefits of using ASTM A106b/A53b Sch40 carbon seamless steel pipe in oil and gas well applications are numerous. From its high strength and durability to its resistance to corrosion and ease of installation, this type of steel pipe offers a reliable and cost-effective solution for transporting oil and gas in harsh environments. By choosing ASTM A106b/A53b Sch40 carbon seamless steel pipe, oil and gas companies can ensure the Safety and efficiency of their operations while minimizing environmental impact.

Comparison of Hot Rolling vs. Cold Rolling Techniques for Manufacturing Carbon Seamless Steel Pipe

Hot rolling and cold rolling are two common techniques used in the manufacturing of carbon seamless Steel Pipes. These processes play a crucial role in determining the quality, strength, and durability of the final product. In this article, we will compare and contrast the hot rolling and cold rolling techniques for manufacturing ASTM A106b/A53b Sch40 oil gas well carbon seamless steel pipe Iron and tubes steel pipe.

Hot rolling is a process that involves heating the steel billet to a high temperature and then passing it through a series of rollers to shape it into the desired form. This process is typically used for producing large quantities of steel pipes quickly and efficiently. The high temperatures involved in hot rolling help to improve the ductility and formability of the steel, making it easier to shape and manipulate.

On the other hand, cold rolling is a process that involves passing the steel billet through a series of rollers at room temperature. This process is typically used for producing steel pipes with tighter tolerances and smoother surfaces. Cold rolling helps to improve the strength and hardness of the steel, making it ideal for applications where precision and accuracy are critical.

One of the key differences between hot rolling and cold rolling is the level of deformation that the steel undergoes during the process. Hot rolling involves significant deformation of the steel, which can Lead to a reduction in Grain size and an increase in strength. Cold rolling, on the other hand, involves less deformation of the steel, which can result in a smoother surface finish and tighter tolerances.

Another important factor to consider when comparing hot rolling and cold rolling is the cost of production. Hot rolling is generally more cost-effective than cold rolling, as it requires less energy and fewer processing steps. However, cold rolling can produce steel pipes with higher precision and tighter tolerances, which may justify the higher cost for certain applications.

In terms of mechanical properties, hot rolled steel pipes tend to have a rougher surface finish and lower dimensional accuracy compared to cold rolled steel pipes. Hot rolled steel pipes are also more susceptible to internal stresses and distortions, which can affect the overall quality of the final product. Cold rolled steel pipes, on the other hand, have a smoother surface finish and higher dimensional accuracy, making them ideal for applications where precision is critical.

Overall, both hot rolling and cold rolling have their advantages and disadvantages when it comes to manufacturing carbon seamless steel pipes. The choice between the two techniques will ultimately depend on the specific requirements of the application, including cost, precision, and mechanical properties. By understanding the differences between hot rolling and cold rolling, manufacturers can make informed decisions about which technique is best suited for their needs.

Importance of Quality Control and Testing in Producing ASTM A106b/A53b Sch40 Carbon Seamless Steel Pipe for Oil and Gas Industry

In the oil and gas industry, the demand for high-quality materials is paramount. One such material that is widely used in this industry is ASTM A106b/A53b Sch40 carbon seamless steel pipe. These pipes are essential for transporting oil and gas from the well to the processing facilities. The quality of these pipes is crucial as any defects or weaknesses can lead to catastrophic failures, resulting in costly repairs and potential harm to the environment and workers.

To ensure the quality of ASTM A106b/A53b Sch40 carbon seamless steel pipes, rigorous quality control and testing procedures are implemented throughout the manufacturing process. These procedures are essential in identifying any defects or inconsistencies in the material, ensuring that only the highest quality pipes are used in the oil and gas industry.

One of the key aspects of quality control in producing ASTM A106b/A53b Sch40 carbon seamless steel pipes is the inspection of raw materials. The quality of the raw materials used in the manufacturing process directly impacts the final product. Therefore, it is crucial to carefully inspect and test the raw materials to ensure they meet the required specifications and standards. This includes checking the chemical composition, mechanical properties, and overall quality of the materials.

Once the raw materials have been inspected and approved, the manufacturing process begins. During the production of ASTM A106b/A53b Sch40 carbon seamless steel pipes, various tests and inspections are conducted at different stages to ensure the quality of the pipes. These tests may include visual inspections, dimensional checks, ultrasonic testing, and hydrostatic testing, among others. These tests help identify any defects or inconsistencies in the pipes, allowing for corrective actions to be taken before the pipes are used in the field.

In addition to the manufacturing process, quality control and testing also play a crucial role in the final inspection of ASTM A106b/A53b Sch40 carbon seamless steel pipes. Before the pipes are shipped to the customers, a final inspection is conducted to ensure that the pipes meet all the required specifications and standards. This final inspection may include visual inspections, non-destructive testing, and dimensional checks, among others. Only after passing these rigorous inspections are the pipes deemed ready for use in the oil and gas industry.

The importance of quality control and testing in producing ASTM A106b/A53b Sch40 carbon seamless steel pipes cannot be overstated. These pipes are essential for the safe and efficient transportation of oil and gas, and any defects or weaknesses in the material can have serious consequences. By implementing strict quality control and testing procedures throughout the manufacturing process, manufacturers can ensure that only the highest quality pipes are used in the oil and gas industry.

https://www.youtube.com/watch?v=q2IbtWO5RVwIn conclusion, quality control and testing are essential in producing ASTM A106b/A53b Sch40 carbon seamless steel pipes for the oil and gas industry. These procedures help identify any defects or inconsistencies in the material, ensuring that only the highest quality pipes are used in the field. By adhering to strict quality control and testing standards, manufacturers can provide reliable and durable pipes that meet the demanding requirements of the oil and gas industry.