Table of Contents

Benefits of Using API 5L X52n Steel Pipe for Industrial Applications

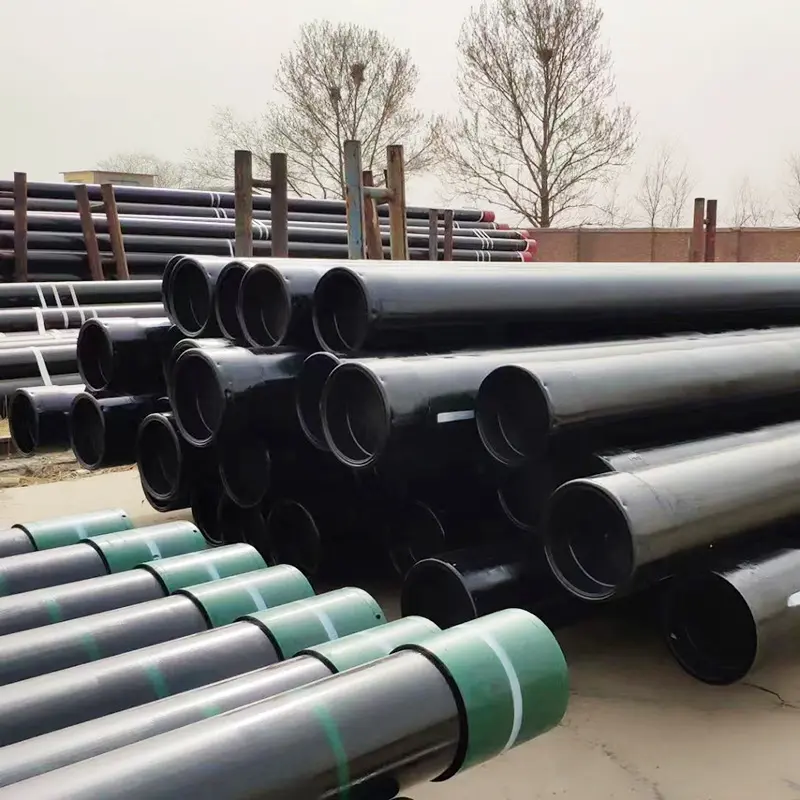

API 5L X52n steel pipe is a popular choice for industrial applications due to its high strength and durability. This type of steel pipe is commonly used in the oil and gas industry, as well as in construction and manufacturing. The ASTM A53 schedule 40 black steel pipe is a specific type of API 5L X52n steel pipe that is designed for use in high-pressure and high-temperature environments.

One of the key benefits of using API 5L X52n steel pipe is its high strength-to-weight ratio. This means that it can withstand heavy loads and high pressures without deforming or breaking. This makes it an ideal choice for applications where strength and durability are essential, such as in the construction of pipelines, oil rigs, and Industrial Machinery.

In addition to its strength, API 5L X52n steel pipe is also highly resistant to corrosion. This is important in industrial applications where the pipe may be exposed to harsh Chemicals, moisture, or extreme temperatures. The black coating on the ASTM A53 schedule 40 black steel pipe provides an extra layer of protection against corrosion, ensuring that the pipe will last for many years without needing to be replaced.

Another benefit of using API 5L X52n steel pipe is its versatility. This type of steel pipe can be easily welded, bent, and cut to fit a wide range of applications. This makes it a cost-effective choice for projects that require custom fabrication or installation. Additionally, the smooth surface of the pipe allows for easy flow of liquids and gases, reducing the risk of Clogs or blockages.

API 5L X52n steel pipe is also known for its high impact resistance. This means that it can withstand sudden changes in pressure or temperature without cracking or breaking. This is important in industrial applications where the pipe may be subjected to extreme conditions, such as in the transportation of oil, gas, or other fluids.

Furthermore, API 5L X52n steel pipe is easy to maintain and repair. The black coating on the ASTM A53 schedule 40 black steel pipe helps to prevent rust and corrosion, reducing the need for frequent maintenance. In the event that the pipe does need to be repaired, it can be easily welded or patched without compromising its strength or integrity.

Overall, API 5L X52n steel pipe offers a wide range of benefits for industrial applications. Its high strength, corrosion resistance, and versatility make it an ideal choice for projects that require durable and reliable piping. Whether used in the oil and gas industry, construction, or manufacturing, API 5L X52n steel pipe is a cost-effective and efficient solution for a variety of applications.

Comparison Between API 5L X52n Steel Pipe and ASTM A53 Schedule 40 Black Steel Pipe

API 5L X52n steel pipe and ASTM A53 schedule 40 black steel pipe are two popular choices for various industrial applications. Both pipes are widely used in the oil and gas industry, as well as in construction and infrastructure projects. While they may seem similar at first glance, there are some key differences between the two that are important to consider when choosing the right pipe for your project.

One of the main differences between API 5L X52n steel pipe and ASTM A53 schedule 40 black steel pipe is their manufacturing standards. API 5L X52n steel pipe is manufactured according to the American Petroleum Institute (API) 5L specification, which sets standards for the production of seamless and welded Steel Pipes for the oil and gas industry. On the other hand, ASTM A53 schedule 40 black steel pipe is manufactured according to the American Society for Testing and Materials (ASTM) A53 specification, which covers seamless and welded black steel pipes for general use.

In terms of material composition, API 5L X52n steel pipe is made from high-strength Carbon Steel, which makes it ideal for use in high-pressure and high-temperature applications. ASTM A53 schedule 40 black steel pipe, on the other hand, is made from low-carbon steel, which is suitable for general-purpose applications where corrosion resistance is not a primary concern.

Another important difference between API 5L X52n steel pipe and ASTM A53 schedule 40 black steel pipe is their pressure ratings. API 5L X52n steel pipe is designed to withstand high-pressure conditions, making it suitable for use in pipelines and other applications where pressure is a critical factor. ASTM A53 schedule 40 black steel pipe, on the other hand, has a lower pressure rating and is more commonly used in low-pressure applications such as plumbing and heating systems.

When it comes to size and dimensions, API 5L X52n steel pipe and ASTM A53 schedule 40 black steel pipe are available in a range of sizes to suit different applications. API 5L X52n steel pipe is typically available in larger diameters and thicker walls, making it suitable for heavy-duty applications where strength and durability are important. ASTM A53 schedule 40 black steel pipe, on the other hand, is available in smaller diameters and thinner walls, making it more suitable for lighter-duty applications where flexibility and ease of installation are key considerations.

In terms of cost, API 5L X52n steel pipe is generally more expensive than ASTM A53 schedule 40 black steel pipe due to its higher strength and pressure ratings. However, the higher cost of API 5L X52n steel pipe may be justified in applications where strength and durability are critical factors.

In conclusion, both API 5L X52n steel pipe and ASTM A53 schedule 40 black steel pipe have their own unique characteristics and advantages. When choosing between the two, it is important to consider factors such as manufacturing standards, material composition, pressure ratings, size and dimensions, and cost to determine which pipe is best suited for your specific application. Ultimately, the choice between API 5L X52n steel pipe and ASTM A53 schedule 40 black steel pipe will depend on the specific requirements of your project and the level of performance and durability needed.

Installation and Maintenance Tips for API 5L X52n Steel Pipe in Various Environments

API 5L X52n steel pipe is a popular choice for various applications due to its high strength and durability. When it comes to installation and maintenance, there are a few key tips to keep in mind to ensure the longevity and performance of the pipe in different environments.

One important factor to consider when installing API 5L X52n steel pipe is the Environment in which it will be used. Whether it is being installed in a corrosive or high-temperature environment, proper precautions must be taken to protect the pipe from damage. In corrosive environments, it is essential to use corrosion-resistant coatings or materials to prevent the pipe from deteriorating over time. Additionally, in high-temperature environments, it is crucial to ensure that the pipe is able to withstand the heat without compromising its structural integrity.

Another important aspect of installing API 5L X52n steel pipe is ensuring that it is properly supported and secured. This will help prevent any potential damage or leaks that could occur if the pipe is not properly installed. It is recommended to use appropriate hangers and supports to ensure that the pipe is securely in place and able to withstand any external forces that may be applied to it.

In addition to proper installation, regular maintenance is also essential to ensure the longevity of API 5L X52n steel pipe. This includes inspecting the pipe for any signs of damage or wear, as well as cleaning and lubricating any moving parts to prevent corrosion. Regular maintenance will help extend the life of the pipe and prevent any potential issues from arising in the future.

When it comes to maintenance, it is important to follow the manufacturer’s guidelines for cleaning and lubricating the pipe. Using the wrong cleaning agents or lubricants can cause damage to the pipe and compromise its performance. It is recommended to use only approved cleaning agents and lubricants to ensure that the pipe remains in optimal condition.

Furthermore, it is important to regularly inspect the pipe for any signs of damage or wear. This includes checking for any leaks, cracks, or corrosion that may have developed over time. If any issues are found, it is important to address them promptly to prevent further damage to the pipe.

In conclusion, proper installation and maintenance are essential for ensuring the longevity and performance of API 5L X52n steel pipe in various environments. By following these tips and guidelines, you can help protect your investment and ensure that the pipe continues to perform at its best for years to come. Remember to always consult with a professional if you are unsure about any aspect of installing or maintaining the pipe to ensure that it is done correctly.