Table of Contents

Benefits of Using 2mm Stainless Steel Wire Rope for Outdoor Applications

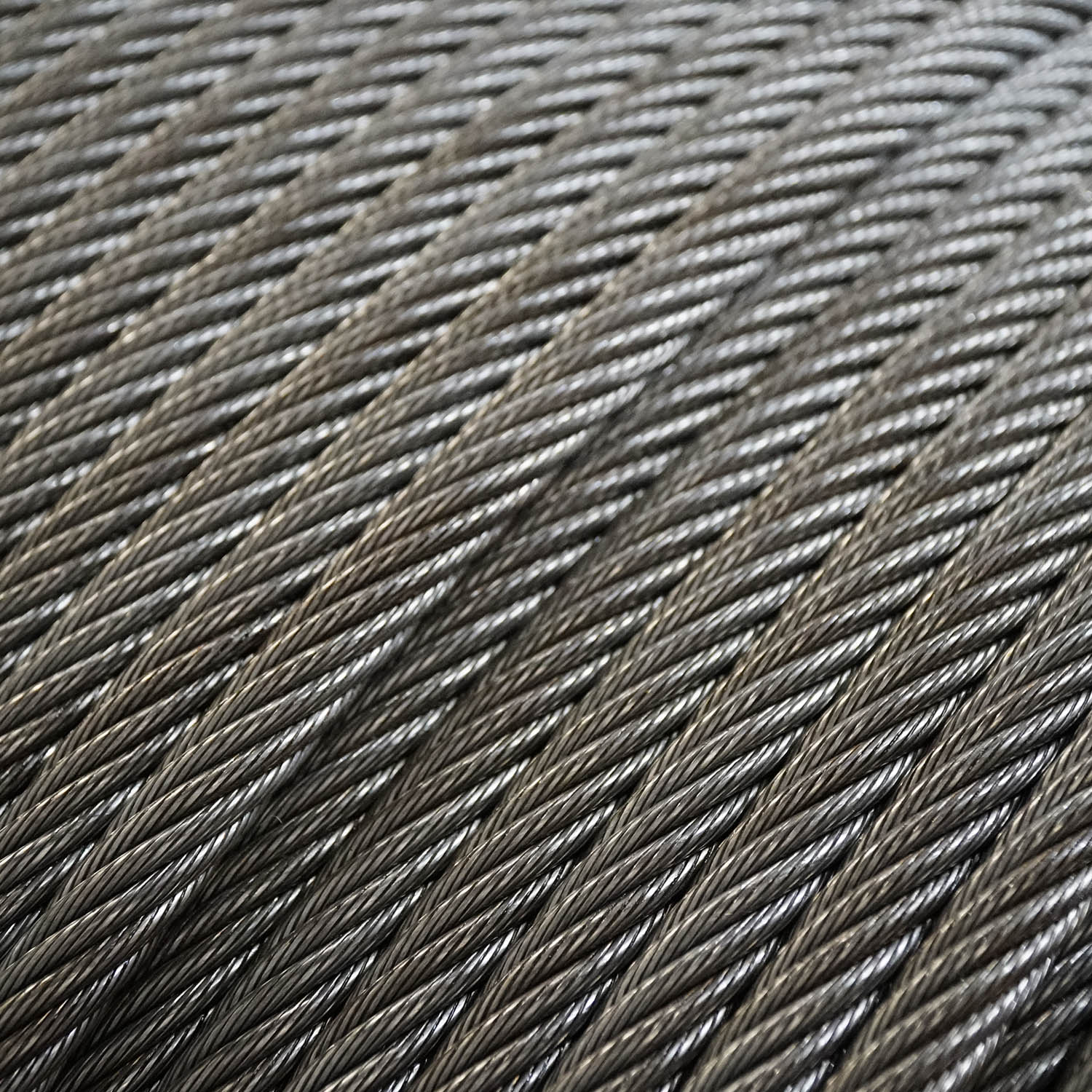

Stainless steel wire rope is a versatile and durable material that is commonly used in a variety of outdoor applications. One of the key factors to consider when choosing a stainless steel wire rope is the diameter of the wire. A 2mm stainless steel wire rope is a popular choice for many outdoor applications due to its strength, flexibility, and corrosion resistance.

When it comes to wire rope construction, one term that you may come across is IWRC, which stands for Independent Wire Rope Core. This means that the wire rope has a separate core made up of individual wires that are laid in a helical pattern around the central strands. This construction provides added strength and stability to the wire rope, making it ideal for heavy-duty applications.

One of the main benefits of using a 2mm stainless steel wire rope with an IWRC core is its high tensile strength. Stainless steel is known for its strength and durability, and when combined with the IWRC core, it can withstand heavy loads and harsh environmental conditions. This makes it an ideal choice for applications such as lifting, rigging, and towing.

Another advantage of using a 2mm stainless steel wire rope with an IWRC core is its flexibility. The individual wires in the core allow the wire rope to bend and flex without losing its strength, making it easier to work with in tight spaces or around corners. This flexibility also helps to reduce the risk of kinking or twisting, which can weaken the wire rope over time.

In addition to its strength and flexibility, a 2mm stainless steel wire rope with an IWRC core is highly resistant to corrosion. Stainless steel is naturally resistant to rust and corrosion, making it ideal for outdoor applications where it may be exposed to moisture, saltwater, or harsh Chemicals. This corrosion resistance helps to prolong the lifespan of the wire rope and ensures that it remains safe and reliable for use in demanding environments.

Furthermore, a 2mm stainless steel wire rope with an IWRC core is easy to maintain and requires minimal upkeep. Unlike other materials that may require regular cleaning or lubrication, stainless steel wire rope is low maintenance and can withstand years of use without losing its strength or durability. This makes it a cost-effective choice for outdoor applications where reliability and longevity are key considerations.

Overall, a 2mm stainless steel wire rope with an IWRC core offers a range of benefits for outdoor applications. Its high tensile strength, flexibility, corrosion resistance, and low maintenance requirements make it a versatile and reliable choice for lifting, rigging, towing, and other heavy-duty tasks. Whether you are working in construction, marine, or industrial settings, a 2mm stainless steel wire rope with an IWRC core is a durable and dependable option that will help you get the job done safely and efficiently.

How to Properly Maintain and Care for 2mm Stainless Steel Wire Rope

Stainless steel wire rope is a versatile and durable material that is commonly used in a variety of applications, from construction and rigging to marine and industrial settings. One of the key components of stainless steel wire rope is the core, which provides strength and stability to the rope. When it comes to 2mm stainless steel wire rope, one important factor to consider is whether it has an Independent Wire Rope Core (IWRC).

IWRC stands for Independent Wire Rope Core, which refers to a separate wire rope strand that is laid in the center of the wire rope. This core provides added strength and stability to the wire rope, making it more resistant to crushing and deformation under heavy loads. In contrast, a Fiber core wire rope does not have a separate wire rope core and is made of synthetic fibers, which may not provide the same level of strength and durability as an IWRC wire rope.

Proper maintenance and care are essential to ensure the longevity and performance of 2mm stainless steel wire rope. One of the most important aspects of maintenance is regular inspection of the wire rope for signs of wear, corrosion, or damage. This can be done by visually inspecting the wire rope for any kinks, broken wires, or rust spots, as well as by running your fingers along the length of the wire rope to feel for any abnormalities.

In addition to visual inspection, it is also important to regularly clean and lubricate the wire rope to prevent corrosion and extend its lifespan. Cleaning the wire rope can be done using a mild detergent and water, followed by thorough rinsing and drying. Once the wire rope is clean, it should be lubricated using a high-quality wire rope lubricant to reduce friction and wear on the wires.

When storing 2mm stainless steel wire rope, it is important to keep it in a dry and well-ventilated area to prevent moisture buildup and corrosion. The wire rope should be stored on a reel or spool to prevent kinks and tangles, and it should be kept away from sharp objects or abrasive surfaces that could damage the wires.

In conclusion, proper maintenance and care are essential for ensuring the longevity and performance of 2mm stainless steel wire rope. By regularly inspecting, cleaning, and lubricating the wire rope, as well as storing it properly, you can extend its lifespan and ensure that it continues to perform at its best. Whether you are using 2mm stainless steel wire rope for rigging, construction, or any other application, following these maintenance tips will help you get the most out of your wire rope and keep it in top condition for years to come.

Understanding IWRC (Independent Wire Rope Core) in Wire Rope Terminology

Wire rope is a crucial component in various industries, including construction, mining, and transportation. It is used for lifting heavy loads, securing structures, and providing support in various applications. One important aspect of wire rope terminology is the IWRC, which stands for Independent Wire Rope Core. Understanding what IWRC means in wire rope is essential for ensuring the Safety and efficiency of wire rope applications.

IWRC refers to a type of core construction in wire rope where the core is made up of a separate strand of wire rope. This core strand is independent of the outer strands that make up the wire rope. The purpose of the IWRC is to provide added strength and stability to the wire rope, making it more resistant to crushing, bending, and fatigue.

One of the key benefits of using a wire rope with an IWRC is its increased breaking strength. The independent core strand adds an extra layer of support to the wire rope, allowing it to withstand higher loads without breaking. This is particularly important in applications where heavy loads are being lifted or moved, as the wire rope needs to be able to support the weight without failing.

In addition to increased breaking strength, wire ropes with an IWRC also have better resistance to abrasion and wear. The separate core strand helps to distribute the load more evenly across the wire rope, reducing the risk of damage from friction and other external factors. This can extend the lifespan of the wire rope and reduce the need for frequent replacements, saving time and money in the long run.

Another advantage of using a wire rope with an IWRC is its improved flexibility. The independent core strand allows the wire rope to bend and flex more easily, making it easier to handle and maneuver in tight spaces. This can be especially beneficial in applications where the wire rope needs to be threaded through Pulleys, sheaves, or other equipment with limited clearance.

It is important to note that not all wire ropes have an IWRC core. Some wire ropes have a fiber core, which is made up of natural or synthetic fibers, such as sisal or polypropylene. While fiber cores are lightweight and flexible, they are not as strong or durable as IWRC cores. Fiber cores are typically used in applications where weight is a concern, such as in Elevator cables or suspension bridges.

In conclusion, understanding what IWRC means in wire rope is essential for selecting the right type of wire rope for your application. Wire ropes with an IWRC core offer increased breaking strength, better resistance to abrasion and wear, and improved flexibility compared to wire ropes with fiber cores. By choosing a wire rope with an IWRC, you can ensure the safety and efficiency of your wire rope applications.